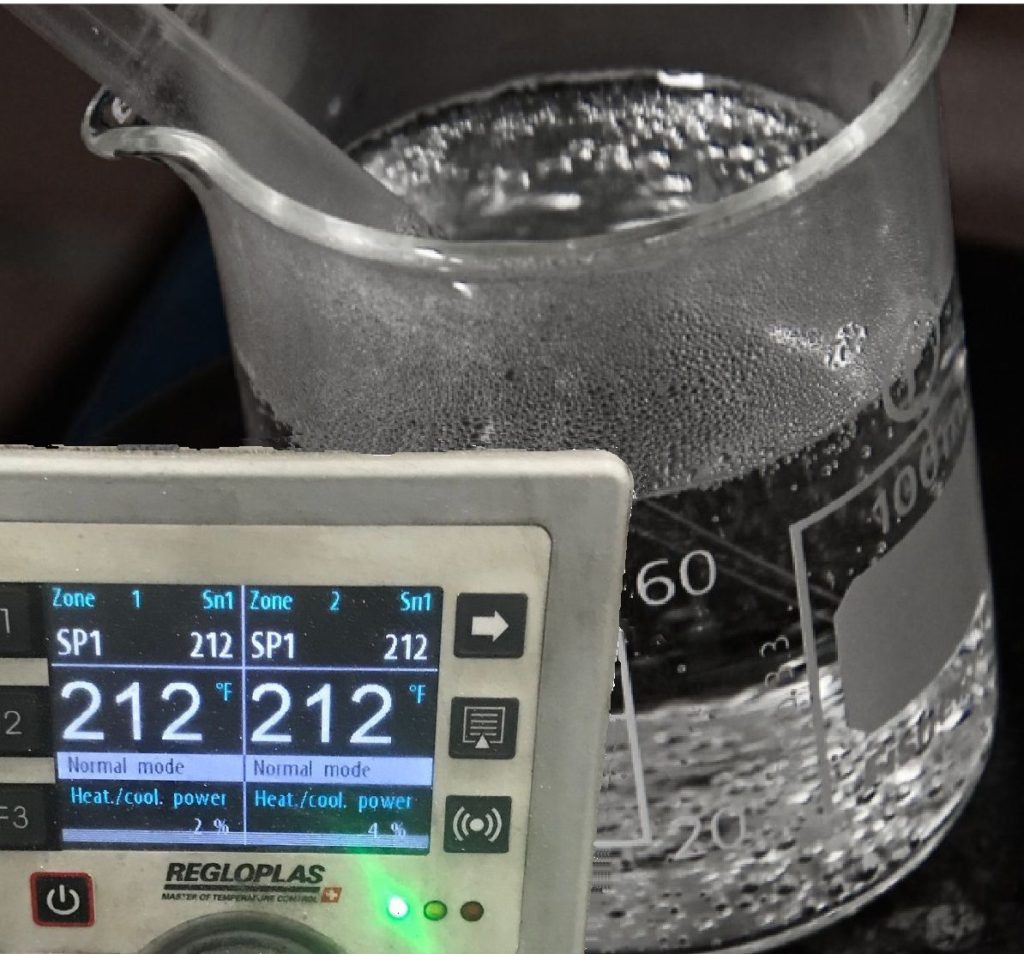

100 degress centigrade is the boiling point of water. Usually die casters wish to keep the water in the die thermal passages below the boiling temperature. This is because the cooling tower water we use contains minerals. The evaporation process that the cooling tower uses concentrates these minerals to the saturation point. If boiling occurs within the die thermal passages the minerals deposit as scale. Scale blocks the thermal heat transfer we require to make good castings. Usually the set temperature of the hot oil units that we use is greater than 100C. During operation the water within the die does not boil because it is flowing. When we shut down for the holidays, setting the hot oil units back to 100C avoids boil out of the water in the die. In many cases the die remains warm enough to avoid start up scrap even whan shut down for a few days. As the picture shows only a small fraction of the power is required to keep the die hot.