Most 3D printed materials have porosity like swiss cheese

Emmentaler Switzerland PDO Cheese image by Dominik Hundhammer

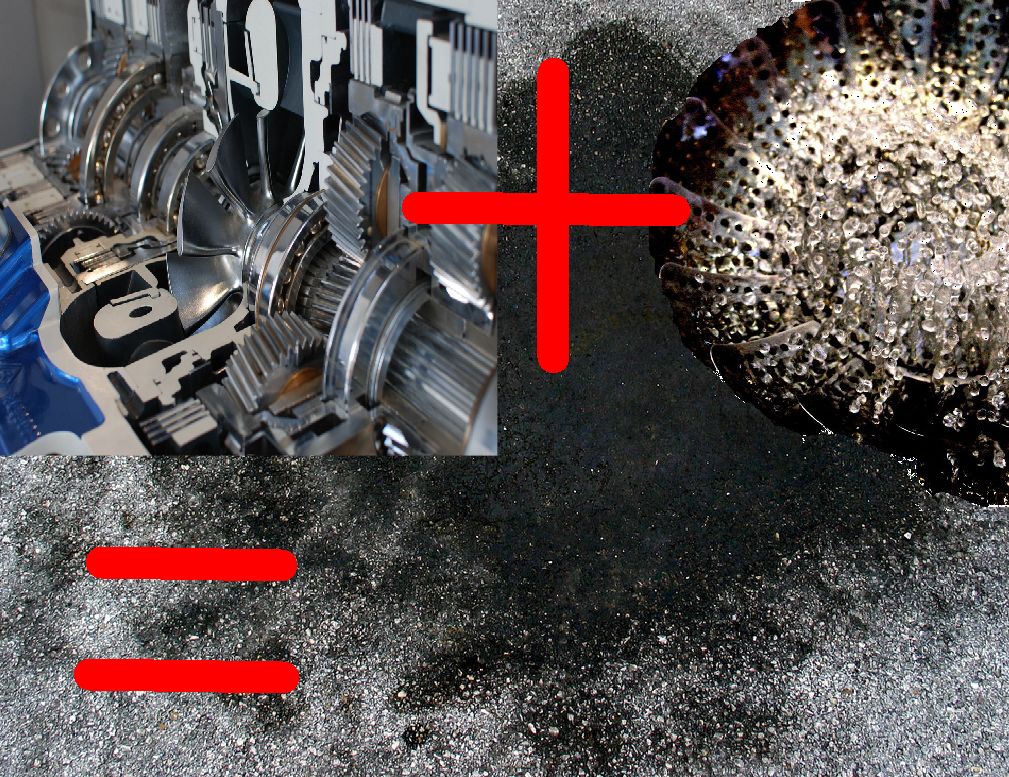

A Transmission + A Seive for a Case = A Driveway Puddle

Oil Stain picture by Christopher Sessums

Seive by DaveMontPhotography

Automatic Transmission by Vestman

When we actually need reasonably porosity free materials it is currently necessary to apply the 3D printing process to creating the mold. We successfully manufacture low volume metal parts by 3D printing a mold made from glued sand. The surface tension of the molten metal retains the metal even though the sand mold is 20% air. A similar strategy is used by Invisalign to make retainers where the high density sheet is vacuum formed over 3D printed molds. It is possible to post process a part with porosity. One of my clients makes aftermarket automotive air conditioning compressors. Freon is a gas and is very difficult to contain. Most car owners would be happy if they never had to refill freon in their car AC system. Even though zero leaks is impossible, as a manufacturer it is our goal. Freon is also used to prevent explosions in high voltages switch gear. When a switch in Downtown New York lost its freon and an killed a hundred or so people ABB enlisted my client to solve their leakage problems because the impregnation cell I set up for them is best in class. Even with that level of impregnation talent, I doubt that the anaerobic sealer we use, can fix 3D SLS (Selective Laser Sintered) metal parts because the pores are too big. Other techniques such as burnishing can be used to create a local skin.

The Burnishing process can increase density

and make a pressure tight skin

Burnished bearing race picture by Jean-Jacques Milan

Burnishing is a cold working process. We use other cold worked materials like cold rolled steel because this process closes the gaps between the grain boundaries to make them pressure tight. The CNC machining centers ability to burnish in addition to cutting is not widely known, but that does not stop me from using this very useful technique.

Invisalign, SpaceX, and GE have discovered that there are niche 3D printing applications. Engineering the product as match to 3D printing, combined with choosing an application that is not affected by material properties such as density, has enabled their marketplace success