3D PRINTING, a current hot news item, is actually the result of a gradual, almost invisible revolution in mold making which has finally reached a transformative point. The point where it can revolutionize the manufacture of equipment, like stock chasers, by making them easily customizable.

THE MAKING OF 3D SHAPES has been at the core of the industrial revolution. It began with 3D wood patterns that were used to create the castings for the earliest steam engines. This was combined with lofting where draughtsmen drew full size drawings of ships on the walls, floors and ceilings of ship yard buildings so that the plates could be cut out and combined to create the great steamships. These early 3D manufacturing processes were very labor intensive and consumed whole lifetimes. They eventually fanned out into the other manufacturing industries. Below, an historic picture of the Ford Rouge tool and die shop shows a whole army of people employed using manual 3D manufacturing methods.

from Library of Congress

Given the number of people involved, the general population had an understanding of these technologies.

CNC 3D MANUFACTURING is a relatively new innovation. CNC milling machines came out in the 50’s and Unimate hydraulic robots began welding cars in the 70’s. Even though computer driven, these devices were fraught with drift problems. In the mid 80’s affordable Computer Numerical Controls, with repeatable positioning accuracy that you could trust, appeared on the scene. This advancement set the stage for the computer to take over many 3D manufacturing tasks.

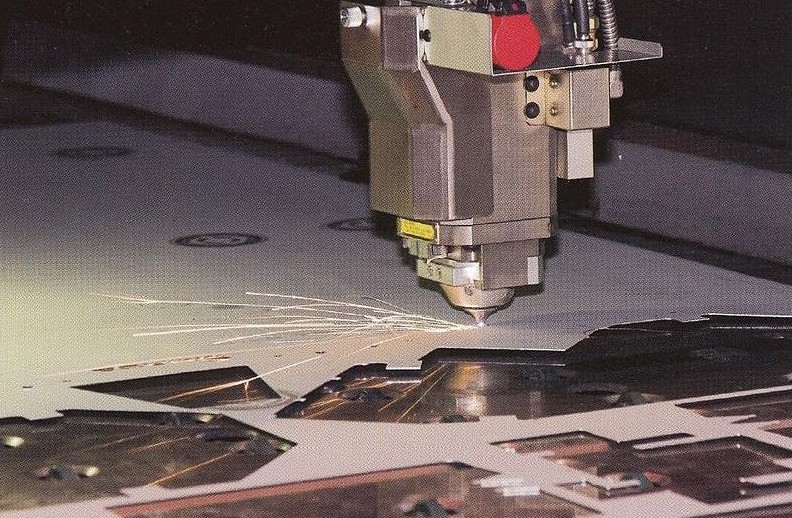

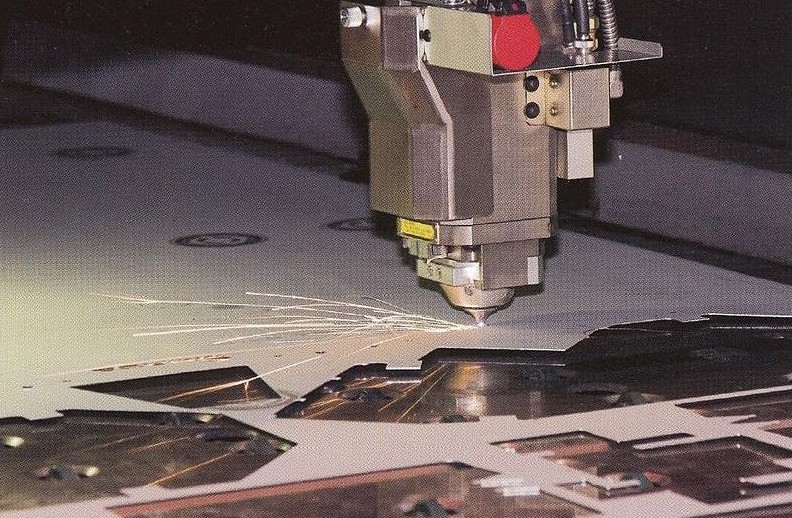

HISTORICALLY, machinery like the bandsaw (shown above) cutting metal sheet were used to make the details that comprise a Wesley Pack Mule frame. Wesley later adopted 3D CNC sheet cutting methods (a picture of a CNC laser guided cutting table is shown below) because our customers deserved the quality and accuracy that they deliver.

The modern CNC control enables these cutting machines to reproduce the desired 3D shapes whenever the customer choses to order.

MORE RECENTLY, advances in 3D printing technologies have made custom mold manufacture an affordable option. Using the 3D mold printing process that Invisalign used to disrupt the orthodontics world, Wesley is 3D printing molds to manufacture Pack Mule components.

(I.materialize additive FDM 3D printer used by Wesley to make molds shown printing parts below).

Photo courtesy of i.materialize.com

EVERYONE IS ATTRACTED to the higher quality and accuracy associated with the modern CNC 3D printing processes. Wesley is pleased to report that the new 3D manufacturing processes enable them to offer the highest quality vehicle with a large variety of user selectable custom options. Since these new 3D manufacturing processes involve a smaller number of workers, to the general population the 3D revolution was not visible and appears to have just splashed onto the screen. Now that it has reached critical speed, we believe “they ‘aint seen nothing yet!”