We want all the drugs we need to cure our personal ailments to be available as generics. The invisible hand of competition as described by Adam Smith, reduces the price we have to pay. This is a good thing if you are the purchaser. On the flip side, none of us wants our market offering to be governed by world competitive pricing. It is very hard to live in an expensive city like San Francisco if you receive a world competitive wage of a dollar a day. Given the fact that most players wish to avoid trying to sell their product on price alone, it is not surprising that most of the products that we buy have non generic features.

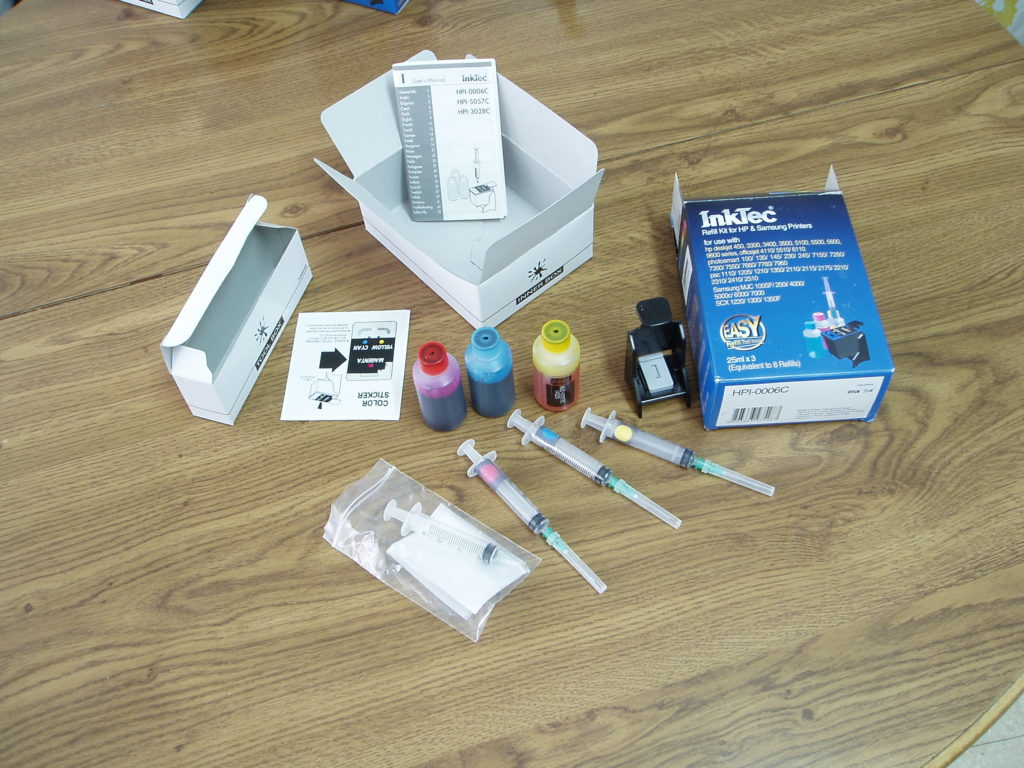

. The pendulum swings back and forth. In the newspaper hey day, generic black ink was sold by the drum. The advent of Xerox machines and ink jet printer swung the pendulum back from the generic side. Even though the ink within the cartridges is generic, encapsulating it in a non interchangeable package made it no longer generic. We all end up paying more than $50 for an amount of ink that would cost a few cents if you could buy it by the drum. The pendulum usually does not remain at full swing. Clever entrepreneurs already sell refill kits, such that it becomes possible to use cheaper generic ink.

Cost analysis in vehicle manufacture would be a whole lot easier if we could build a vehicle entirely from generic parts. This would be a good match to the management simplifications like competitive bidding. Certainly it would be convenient to believe that price is the only difference. The reality is that all companies strive to create competitive advantages. Even though it is possible in most cases to find three suitable suppliers for every component, swapping suppliers usually involves opportunity costs like drawing changes, testing, retooling charges and set-up bills. This spills over into even the launch process where modern MVP (minimum viable product) strategies cause drawing updates between prototype and product reflecting the part design differences between those made by vendors who specialize in low volume rapid delivery and those made by vendors who specialize in lowest manufacturing cost.

The Lean Innovator

Lean Engineering Solutions to Improve Profitability in the Areas of Manufacturing, Material Handling and 3D