What sort of parts are well suited for the rheocasting process?

The rheocasting process can be utilized on all aluminum parts normally made by the die casting process. Most aluminum foundries discover that rheocasting can deliver a cheaper manufacturing cost when compared to conventional die casting on new installations due to faster cycle time and longer die life.

It is normally profitable to retrofit rheocasting into existing production cells in a number of product categories.

Parts with high die wear

Fuel rail

Parts in alloys other than 380 or 383

Parts with thick walls

Knuckles

Suspension brackets

Engine brackets

Parts with high tensile loads

Control arms

Wheels

Parts where cast surfaces can replace machined surfaces

Brake cylinders

ABS valve housings

Pressure tight components

Freon tight AC housings without impregnation

Rack and Pinion Housings

Why is rheocasting normally used on high volume parts?

The manufacturing of molds which are capable of withstanding the high metal pressures needed to create high integrity parts is costly. A break even point verses machining from blocks or extrusions occurs at a volume of about 10,000 shots per year.

In selected special cases lower volumes can be economical, especially if a significant machining tooling cost can be saved by utilizing the net shape capabilities of rheocasting

Is the rheocasting process faster than conventional die casting?

All of the rheocasting process elements occur in a shorter time than conventional die casting

The dwell time is shorter due to less heat input

The spray time is shorter due to less heat input

The metal can be loaded into the sleeve before the die completely closes

Whether the machine actually runs a faster cycle is related to whether the chosen rheocasting metal preprocessing equipment can deliver processed aluminum at a synchronized faster pace. In the best rheocasting cells it has been possible to increase yield by 50% Faster casting cycles are needed to justify the extra rheocasting metal treatment cost

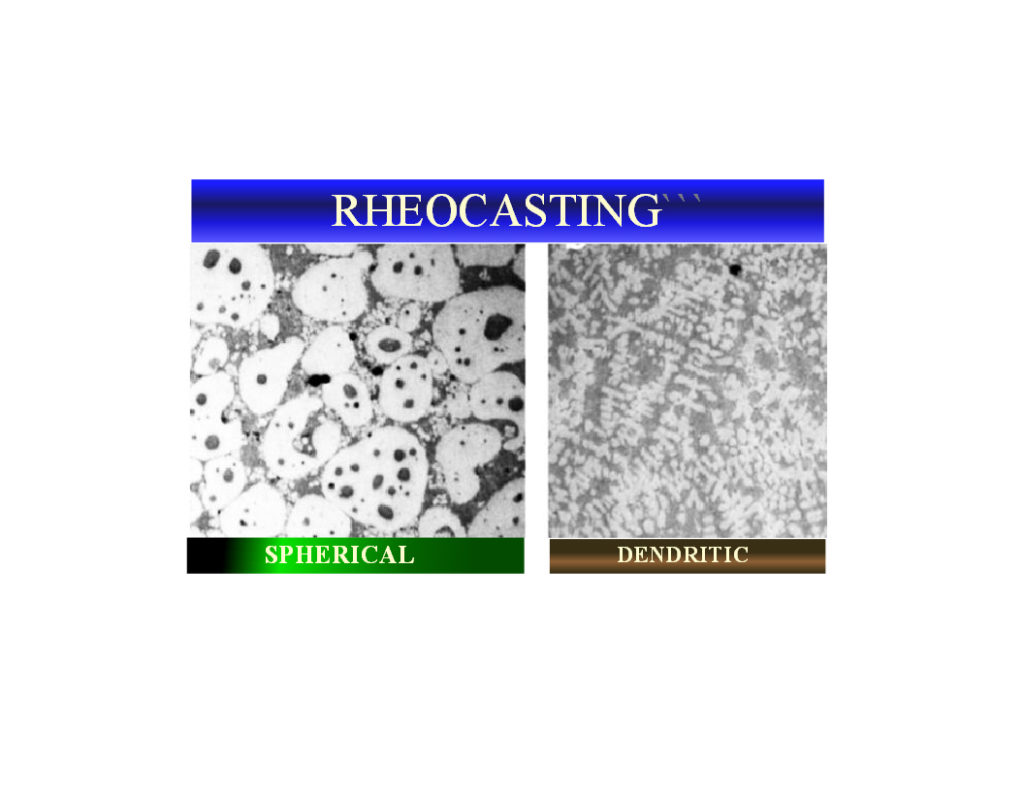

What is the big deal with spherical grain structure?

Both the casting producers and the casting users are attracted to aluminum casting with a spherical grain structure. This structure is normally only possible by using the rheocasting variation of the die casting process.

The normal die casting process creates castings with dendritic structure. These castings are more brittle. The casting producer fights with “hot short” cracking. The casting end user find dendritic structure castings unsuitable for applications like vehicle frame and suspension parts where tensile strength and elongation are required.

The original MIT Fleming rheocasting process also achieved a dispersion of defects. Recycled secondary aluminum alloys are up to 5% non metallic by weight (mostly aluminum oxides) Due to the laws of physics these non-metallics get concentrated in specific locations within a normal die casting causing weak spots. The stirring action of the magneto hydrodynamic stirring process that Fleming used to create spherical grain structure also dispersed the defects. This resulted in a casting with superior tensile and elongation properties. Both the casting user and producer are attracted to achieving this result employing secondary (recycled) alloys because they are half the price of primary alloys. Other rheocasting processes that have been developed since for preprocssing metal to create spherical grain may not achieve the same dispersion of defects as the original MIT method.

Casting producers like the spherical grain structure because it is easier to inject metal into the die. This is most importantly true during the intensification phase of the injection where additional metal is pumped into the cavity to fill the voids caused by metal shrinkage during solidification.

Why would you want squeeze pins in a Rheocasting?

Even in rheocastings where a 60% solid fraction is chosen (such as master brake cylinders) 40% is still liquid. This liquid material will shrink as it solidifiies. If you can employ thick gates and the heavy sections can be fed from the biscuit, squeeze pins are not needed. In real castings heavy sections are usually isolated from the biscuit and runner. In these castings a squeeze pin is an effective way to fill in the shrinkage porosity. In normal die casting a squeeze pin has a 5000 piece life. This assumes that the squeeze pin design is that good. In a master brake rheocasting at 60% solid fraction the squeeze pin life is 100,000 shots. This is a powerful example of the effect of rheocasting on die life

two succesive shots with the squeeze cycle turned off on the left casting