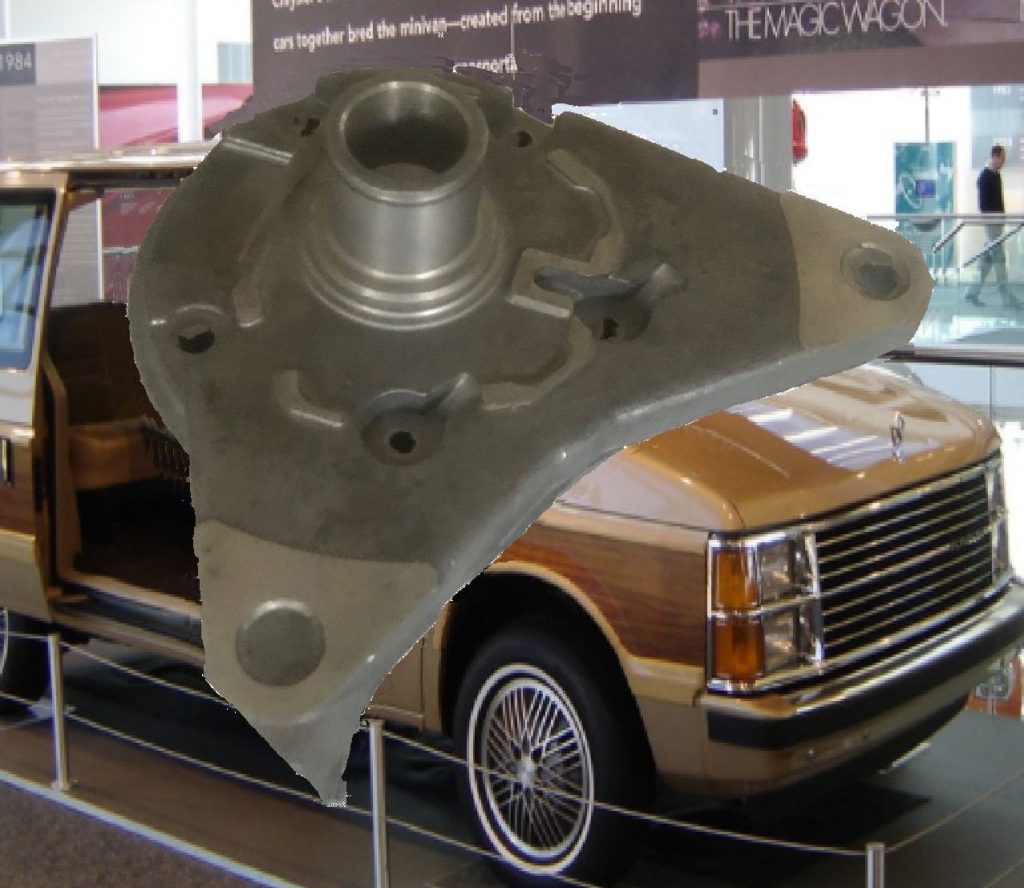

At the beginning of my HPDC career, the demise of Dohler Jarvis, who invented pressure pins, resulted in the transfer of the dies for the pictured AC front cover to the Chrysler casting plant where I worked. In a panic we not only needed to learn to run these die with pressure pins, but also needed to avoid Dohler pressure pin patent infringement. Many years later I was working with a small air conditioning compressor rebuilder who needed replacement front cover castings. It turned out that mini-vans had a heavy duty cycle that caused the front mount ears to break off of this casting at about 125,000 miles. The normal strategy of buying replacement castings from the original casting supplier was not possible because Chrysler wanted to sell complete replacement air conditioning compressors.

I was also working with a small start-up rheocasting casting plant at that time. The higher ductility 356 semi-solid material was a natural choice to solve the ear breakage problem. The rheocasting process is very effective at making freon tight castings. The only remaining problem was coming up with a casting die at an affordable piece cost. We no longer had the 1,000,000 + annual volume to justify spending $250,000 on a 4 cavity die

Because our total manufacturing volume was estimated to be only 50,000 pieces, we elected to make a single P20 cavity in a unit die. This was copied from the strategy we use for creating dies for prototype castings. The dies for making the original part were cut from the original wood patterns. Thus the part print lacked all of the dimensions needed to CAD create a complete 3D model. We found a complete casting from cavity 31 and used it

to create a 3D CAD model. Since the sample was a machined part we chose and added in machine stock to make a model for the casting. Selected surfaces that were originally machined were made as cast taking advantage of the reduced heat check of the rheocasting process. We omitted the original pressure pin substituting a gate cut off with a cold saw such that the shot biscuit would serve as a pressure pin. Interestingly it was unnecessary to impregnate this casting even though the air conditioning compressor rebuilder already was geared up to impregnate the other castings that he bought and machined.