The old addage “If the only tool you have is a hammer, every problem is a nail” Eliminating sharp edges fit into the same category “if the only tool you have is a chamfer ever corner is at a 45 angle” Imposing a one size fits all solution to a problem creates sub optimum results. This discussion is about adding counter bores to your design arsenal.

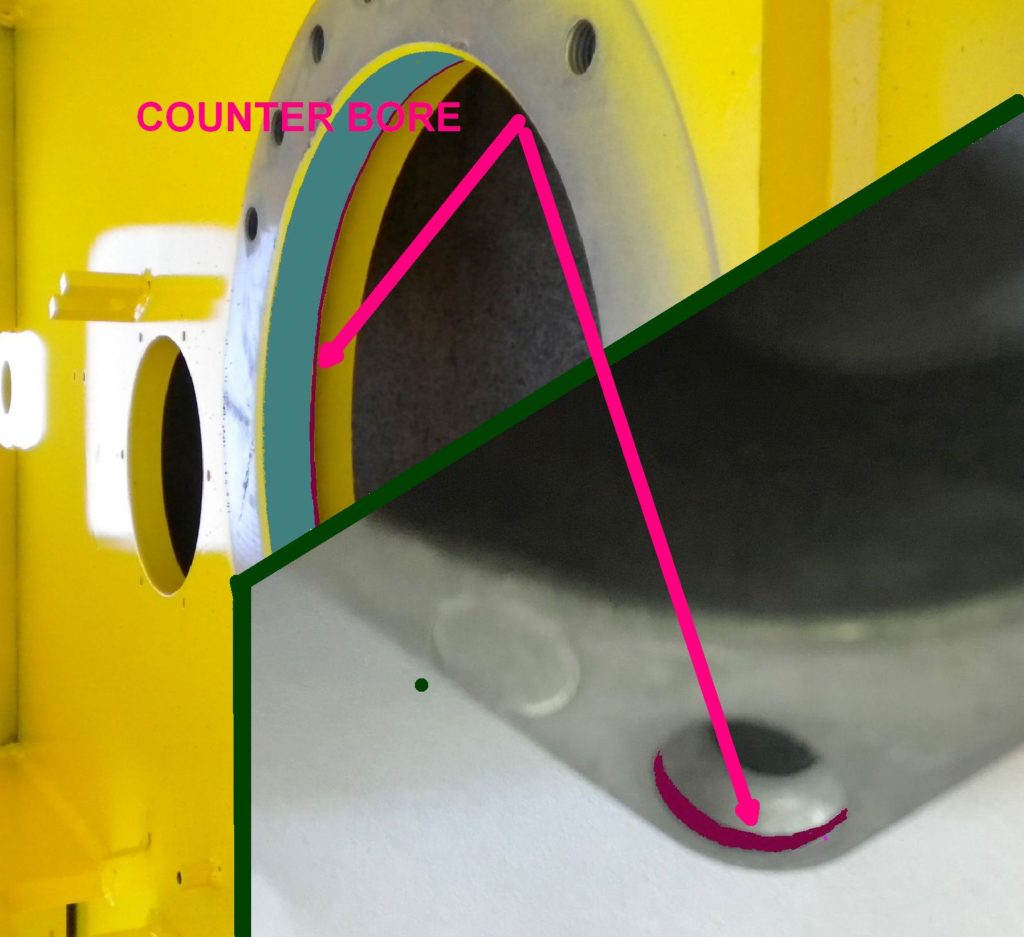

Machined 45 degree chamfers work very well when both adjacent surfaces are machined. In the picture you see a yellow 45 chamfer on the corner from the mounting surface to the bore. This was machined into the plates. On the opposite end of the bore a counter bore replaced the chamfer. This counter bore is on the corner between a unmachined face and the bore. The counter bore was created by interpolating the bore roughing cutter. This resulted in a uninterrupted cut by the fragile finish bore cutter which solved a cutter chipping problem,

Cast counter bore are used when a machined surface connect to a cast chamfer. The counter bore solve the tolerance issue and insures that the chamfer diameter is never oversize.