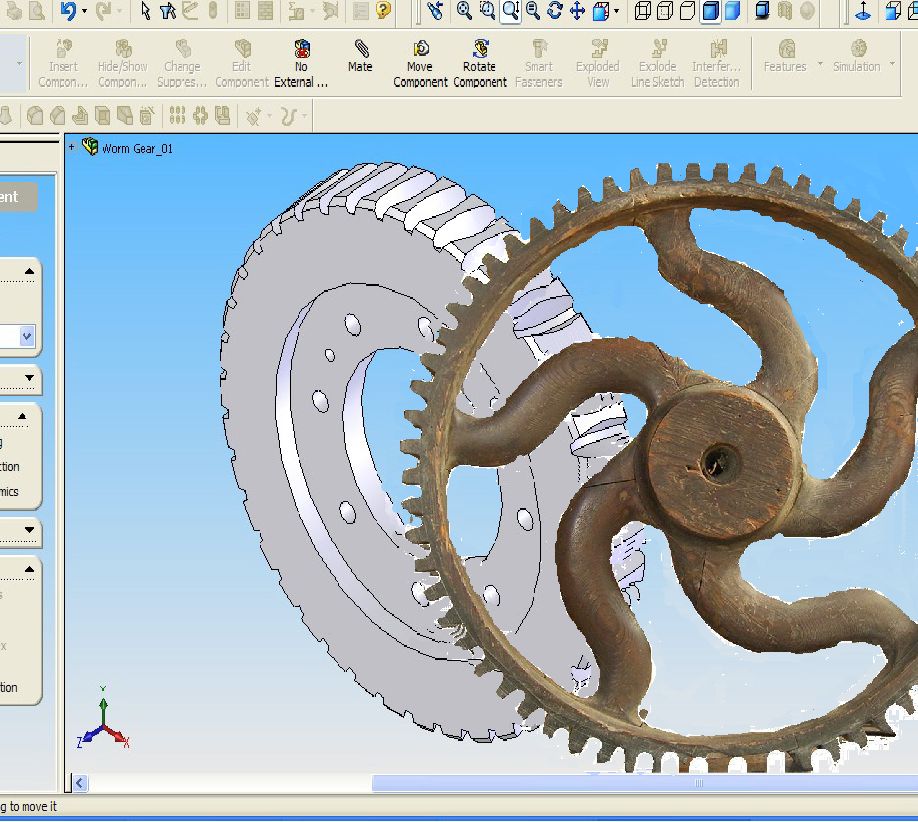

The value of additive manufacturing has long been known to the human race. Early civilization discovered the benefits of layering clay to create the pottery containers that we use for every day life. Most of us do not give a second thought to the pottery cups that deliver our morning coffee. Linking a coffee cup to additive manufacturing might not be obvious even if you work in the factory that makes coffee cups. A coffee cup factory is all about making an identical copy for everyone. After a coffee cup is designed using additive manufacturing, it is given to the pattern makers. Their precision wood patterns capture the shapes and serve to guide the creation of molds and tooling. This became the backbone of industrial manufacturing until the 1990s when the mathematics within the CAD and CAM programs evolved to replace wood patterns. Some of the bits of craftsmanship such as the “S” shaped gear spokes that keep the gear round during casting cooling have been lost from modern designs. The STEM skills required for the shape definition task are unchanged even though the practitioners are now called CAD modelers instead of pattern makers. The commercially useful shapes still require corner radii and fillets. Fits, blends, dimensional accuracy and finishes are even more important. As we evolve to a mass customization marketplace more people with this skill will be required.

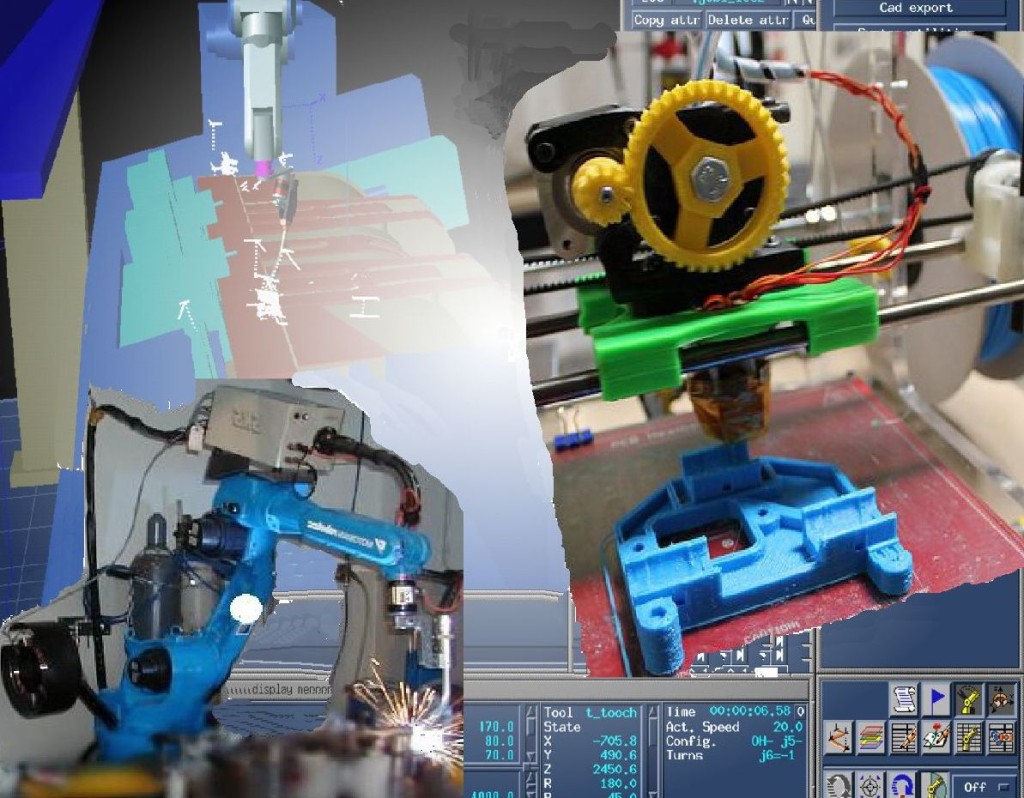

Convergence is a term used to describe the effect that advancements in computer technology is having on the communications industry. The line between telephone, television broadcast, radio, paging, security, satellite, cable, and internet companies is blurring. The same is happening in additive manufacturing. A robot arc welder heats material fed as a wire and fuses it in a predetermined position controlled by a multiaxis CNC control. Interestingly enough, this is the exact description of what happens in filament style 3D printing. As we evolve away from one size fits all, it will become possible to manufacture locally the items that we want. Computer controls will add the necessary flexibility to the production equipment that we own and recognize.

The Lean Innovator

Lean Engineering Solutions to Improve Profitability in the Areas of Manufacturing, Material Handling and 3D