Retrieval

As a young boy, my family had a old phonograph. This machine came from the Rockefellers because one of my great aunts was a domestic servant. One of my uncles had worked at a radio station so we had a small case of the 78 records to match. As a budding engineer I was fascinated by the wind up mechanism that spun the turntable. Retrieval is what I liked best. I could play my favorite records any time that I wanted to hear them. The phonograph was one of the first data storage devices. It could capture and store music or speech. It was the retrieval as desired that made it popular. A whole orchestra could surround you within your own living room. The quality of that retrieval was inverse to the popularity. The records that were played the most often picked up the scratches. Some of our favorite records deteriorated to the point where we no longer enjoyed listening to them.

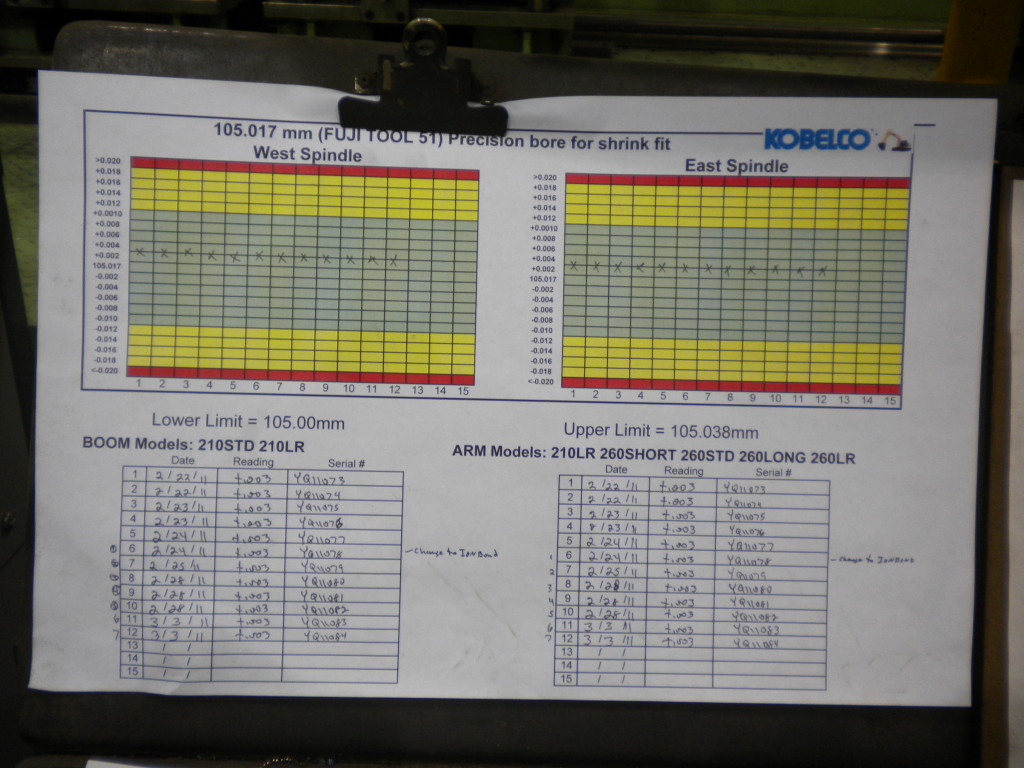

One of the more important aspects of retrieval is data integrity. Just like scratches spoil the usefulness of a record, a corrupted bit can spoil a CAD data file. Back when I was directing the designers at Lotus in Norwich England how to create my patented GM engine component, it was necessary to transfer CAD data on magnetic tapes. Even though the internet could transfer data from Canada to England at the time, the transfer usually had corrupt data. This made for a lot of trips by plane. England is a lot farther North and it is dark at 4:00 PM in November. Obviously the data communication protocols that we currently use today automatically correct static. (Skype saves a lot of plane trips) As an aside, we even have programs that can edit the scratches out of music recorded on old-fashioned phonograph records.

A phone call from the IRS strikes fear into most people. We know that this is a time that retrieval is going to be vital. Unfortunately, our accounting friend Darryl Engebregson, who could remember all of his clients data three years back has passed away. We still talk about his answer to an IRS query where he said “That number sounds familiar.” This experience caused us to arrange our http://mileagetrakker.com business so that it is possible to retrieve mileage records from three years ago. This is a match to the IRS audit schedule. None of us want to face the penalties that the IRS charges when they disallow a few years of deductions when we cannot retrieve our records.