Those of us who actually go the extra mile know that you really have to travel a little bit farther than that to get the job done.

Jesus declared in the Sermon on the Mount “Whoever forces you to go one mile, go with him two.” (Matthew 5:41, (NASB)) “impressment” allowed a Roman soldier to conscript a non Roman citizen to carry his equipment for one Roman mile (milion = 1,000 paces, about 1,611 yards)– no easy task considering a Roman soldier’s backpack could weigh upwards of 100 pounds (45.4 kg).

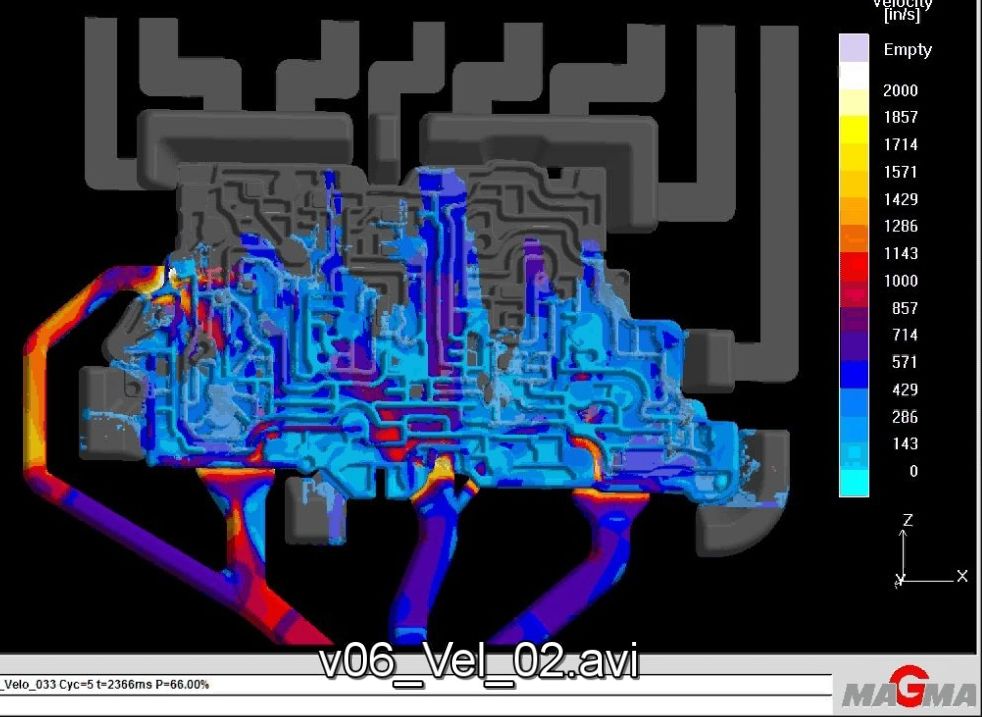

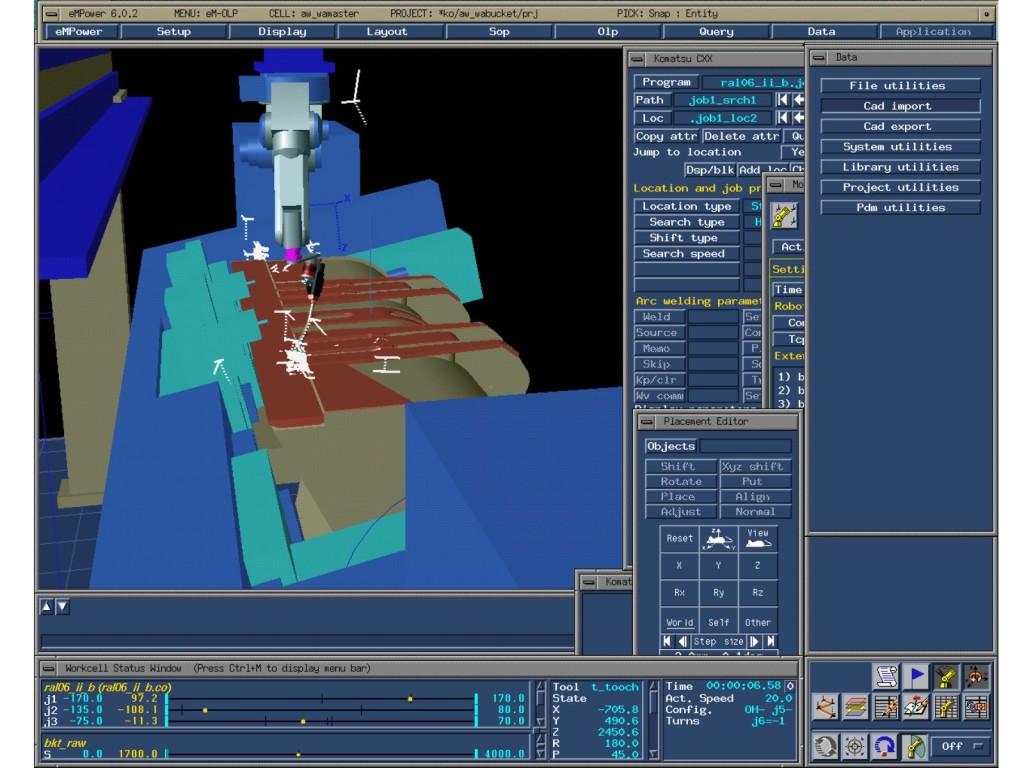

The concept of the extra mile applies heavily to quoting contract manufacturing. After you learn to quantify and price everything it takes to do a job, you discover that you also have to plan for the extra mile. This reflects the fact that everything will not go perfectly. Most industries have a multiplication factor before profit which is applied to the computed cost. This adjusted cost is a much more realistic value when the accounting is done at the end. This type of feedback loop is embedded in making a profit. It would not have been possible for me to turn around a few manufacturing companies without basing these factors on historical experience. The fact that all projects have built in inefficiency creates a lean consulting industry.

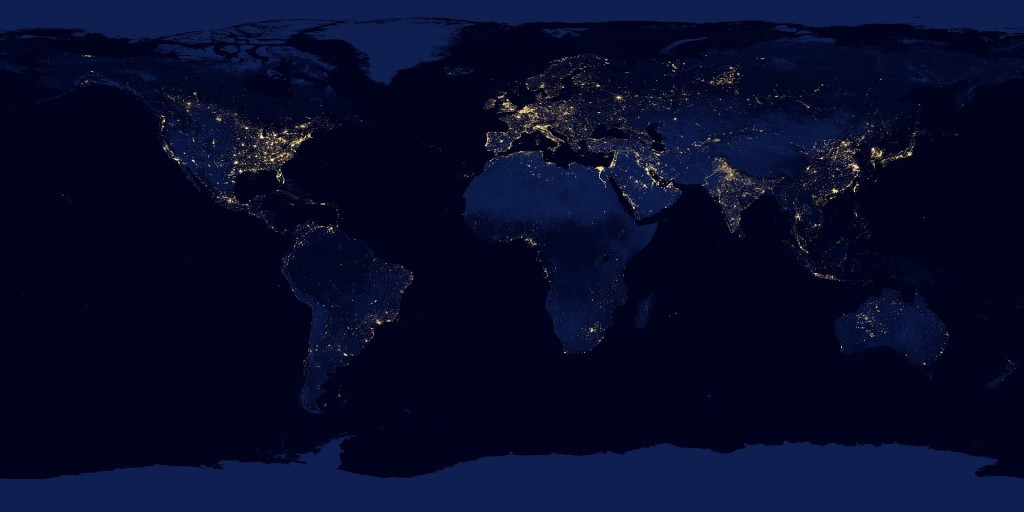

The volatile nature of employment these days causes many people to put in the extra mile on the highway in traffic jams. Not everyone clocks the extra mile willingly, as Jesus suggested, which is why we hear about road rage.

. Our daughter when she was young was stuck in traffic with her mother. She weighed in on the topic. “You know traffic has an end. You just have to go there.” Ah! Wisdom out the mouths of babes. For those of us who are unable to go to traffic’s end, we need to adjust to the longer commutes. Many people who drive for business find that the old approximate methods of estimating mileage for their expense reports miss some of the miles needed to make the actual trip. This is why people who choose to use a www.mileagetakkker.com device to automatically tabulate their trips in IRS format end up money ahead.

. Our daughter when she was young was stuck in traffic with her mother. She weighed in on the topic. “You know traffic has an end. You just have to go there.” Ah! Wisdom out the mouths of babes. For those of us who are unable to go to traffic’s end, we need to adjust to the longer commutes. Many people who drive for business find that the old approximate methods of estimating mileage for their expense reports miss some of the miles needed to make the actual trip. This is why people who choose to use a www.mileagetakkker.com device to automatically tabulate their trips in IRS format end up money ahead.