We have all gotten excited by the 5S shine concept until we got out into the plant and tried to accomplish it at a reasonable cost. This is when it becomes evident if the manufacturing cell was set up with service in mind. In my career it has been necessary retrofit serviceability into a few plants that were not profitable because they had excessive down time. I would like to claim that I reinvented the equipment so that it never broke, but the technology to accomplish that approach is still way in the future. What I could do is speed up the process for repairing the equipment when it did break. This task would be easy if it only involved changing one item. The reality is that serviceablity is doing a whole bunch of little things right.

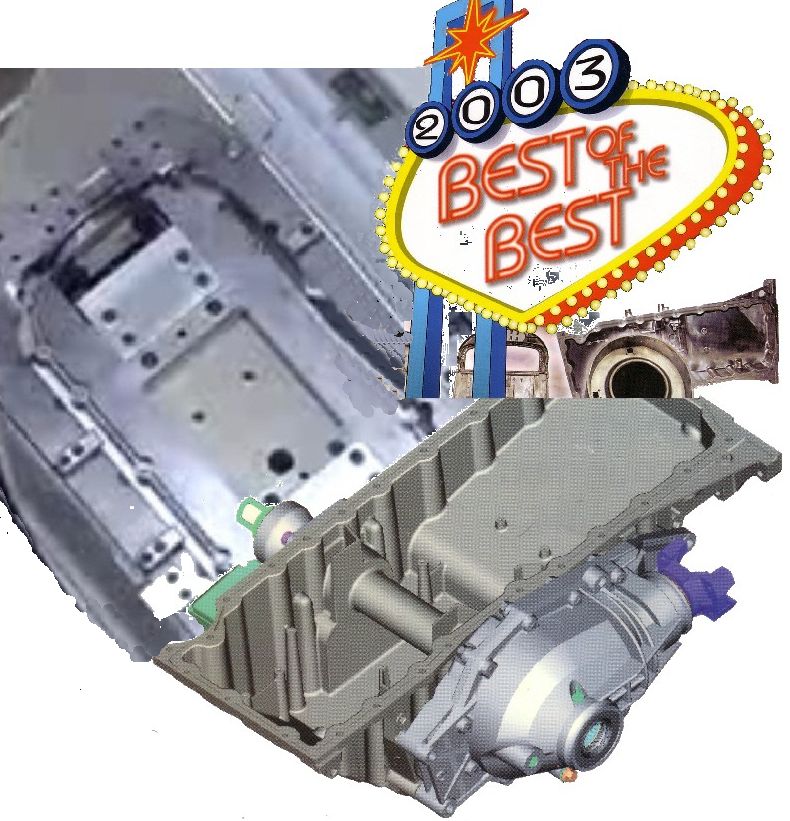

I have chosen to highlight a some examples that I recently implemented on a 3500 Ton Prince Die Cast cell at Cana-datum.

1) Captivated bolts on guards – A surprising amount of machine repair time is lost simply looking for the bolts to reassemble after a repair. I discovered that washers welded to the bolts kept them from getting dropped and lost.

2) Hook on guards. I only use one bolt to attach my guards to the machine so that I conform to the safety standard for bolted guard. I turned around a plant loosing millions per year by changing guards

with 20 or so bolts into hook on guards with a single bolt.

3) Maximized crane drop in access by routing utilities in banks.

4) No utilities below floor level

5) Platform without leg bracing bolted at deck level instead of concrete floor anchored

6) Modularized platforms, auxiliary equipment – The items surrounding the main equipment can be quickly removed because they are in manageable chunks that can be moved with a lift truck.

7) Sweepable floor. Everything is off of the floor or contained with closed bases so that floor dry can be quickly removed when the spills occur.

8) All electrical junction box covers accessible without disassembly