Aluminum has an affinity for most metals. In aluminum high pressure die casting this shows up as solder build up. One useful exception is the black oxide ceramic surface layer that form on H13 (or H11) when it has a grain structure related to R 44 to 50 hardness. The high pressure die casting process is based on using this exception. (A matte surface finish to hold release is also required)

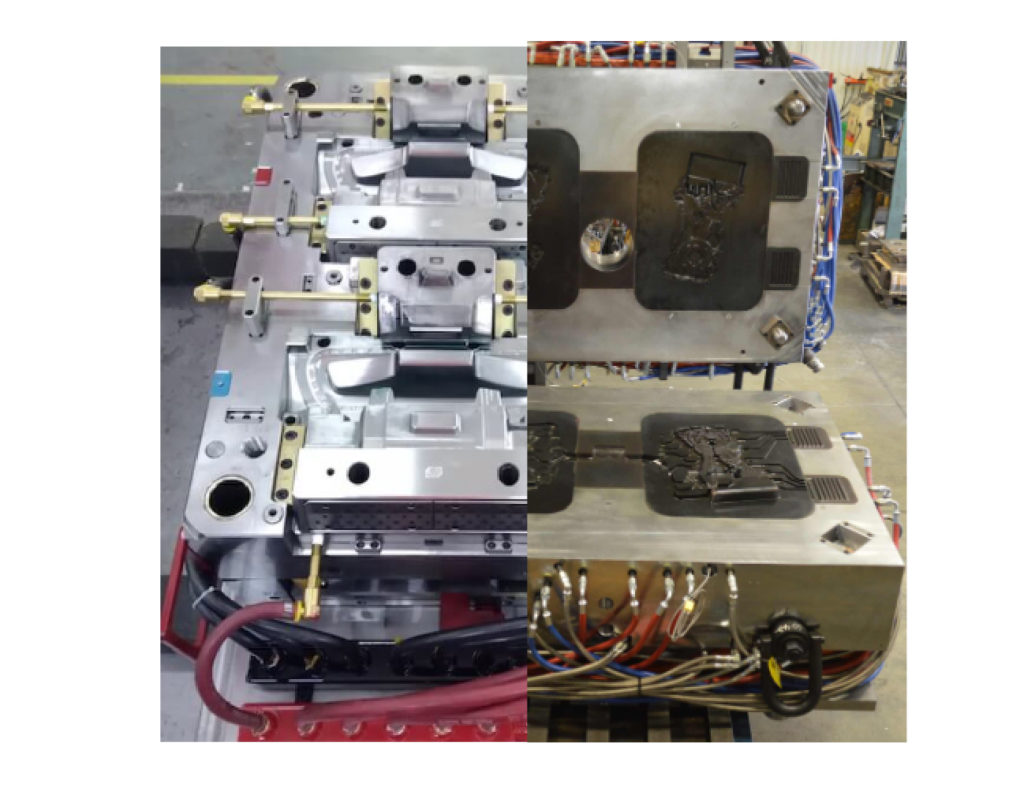

In my displayed picture I have shown a new plastic injection mold tool next to a new die cast tool. I will leave you to determine which example is the die cast tool. If you can succeed in making the correct determination (the die cast tool is on the right) you can do receiving inspection on incoming new die cast tools. Tools without the black oxide matte surface finish were made using the significantly less costly steps used to create a plastic injection mold

The only question when a “completed” die is found without a Rc 44-49 black oxide matte surface is whether the purchase specification required it.