User Invisible

The best companies know their customer so well that they are able to provide their offering almost invisibly. This is refreshing in an era where we are bombarded at every turn by another ad message seeking our attention. There are a couple of so called recruiting firms that spam my e-mail daily, to the point where I will have nothing to do with them — ever. If they show that level of insensitivity to the candidates whom they believe should buy their service, I can imagine how they appear to the companies who are hiring.

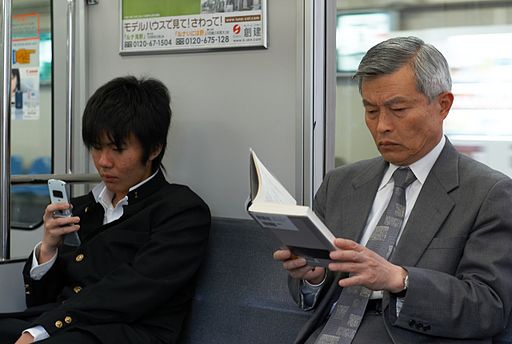

Texting is a good example of user invisible. The using public is very comfortable with text messaging because it has been around for a long time. In 1933 RCA Communications, introduced the first “telex” service between New York and Europe. My dad’s best friend, a NASA electrical engineer HAM radio enthusiast, carried on a radio telex conversation with a friend in South Africa long into the night when the fickle strength of the nighttime ionosphere permitted it. The rest of us had to wait for texting to become a feature of our cell phones. In 1995 Telecom Finland and Radiolinja in Finland offered cross-network SMS (Short Message Service) functionality which began the modern back bone for cell phone texting. Today, in countries such as Finland, Sweden and Norway, over 85% of the population use SMS. The European average is about 80%, and North America is rapidly catching up with over 60% active users of SMS as of the end of 2008.

The brevity of the text message is appreciated by the users and the carriers alike. The 160 character size (invented in 1985 by Friedhelm Hillebrand while he was working for Deutsche Telekom) of a text message enables transmission of 350 text messages in the bandwidth required to send a single phone call. The users experience this simplicity as an affordable price. Text messaging services can feel particularly intimate because they talk like humans. Digital users who type “thank you” after the software executes a command instantly get a “you’re welcome.” The barriers to using a new service are also lower, because there’s nothing to download. In a February blog post, Jonathan Libov, an analyst at venture capital firm Union Square Ventures, recounts standing at a New York City bus stop and having another passenger tell him about Bus Time, which lets people text the Metropolitan Transit Authority to find out how long they’ll have to wait for the next bus. His first thought: “Thank God I don’t need to download another f—ing app for this.”

When we were inventing http://mileagetrakker.com we chose a hybrid approach. Our beta testing proved that the users wanted to choose an interface that matched their lifestyle. The nice part of a connected car service is that we know when the vehicle is actually driving. Our cloud based interface does not get the users into trouble by having them text and drive. Selected users find it easiest to record the business purpose of the trip as they walk away from their vehicles.

Product Hunt introduces 10-20 new smart phone applications every day. This is a lot more than will ever fit into my smart phone. Gartner analyst Ken Dulaney said in a statement: “Our analysis shows that most mobile applications are not generating profits and that many mobile apps are not designed to generate revenue, but rather are used to build brand recognition and product awareness or are just for fun. Product Hunt now lists over forty offerings that use text instead of an application as a user interface. Text is a trend that is growing.