ENDURANCE LIMIT

In fatigue testing, the maximum stress which can be applied to a material for an infinite number of stress cycles without resulting in failure of the material

Mc Graw-Hill Dictionary of Architecture and Construction Copyright @ 2003

We reached a new milestone. The average age of registered cars in the US is now 11.5 years. This is probably the high water mark. There are a number of factors behind this assertion.

(1) The automakers are only required to stock service parts for 10 years. This means that it might not be possible to get repair parts for more than 1/2 the cars that are on the road in the portion of the vehicle life that they are needed.(Aftermarket repair parts are available for most high volume models- usually only about 2/3 of the cars made). Purchasing a used Smart car because it has an attractive price, may not look so smart after it is 10 years old and no service parts are available.

(2) The economy is slowly improving.

(3) Probably most significant is that the government imposed rapid fuel economy improvement targets. To meet those targets, the current crop of new cars is being built out of light weight materials that have not been in vehicle use for 10 years.

Today’s fuel efficient cars are made from lightweight materials that do not have a longevity history.

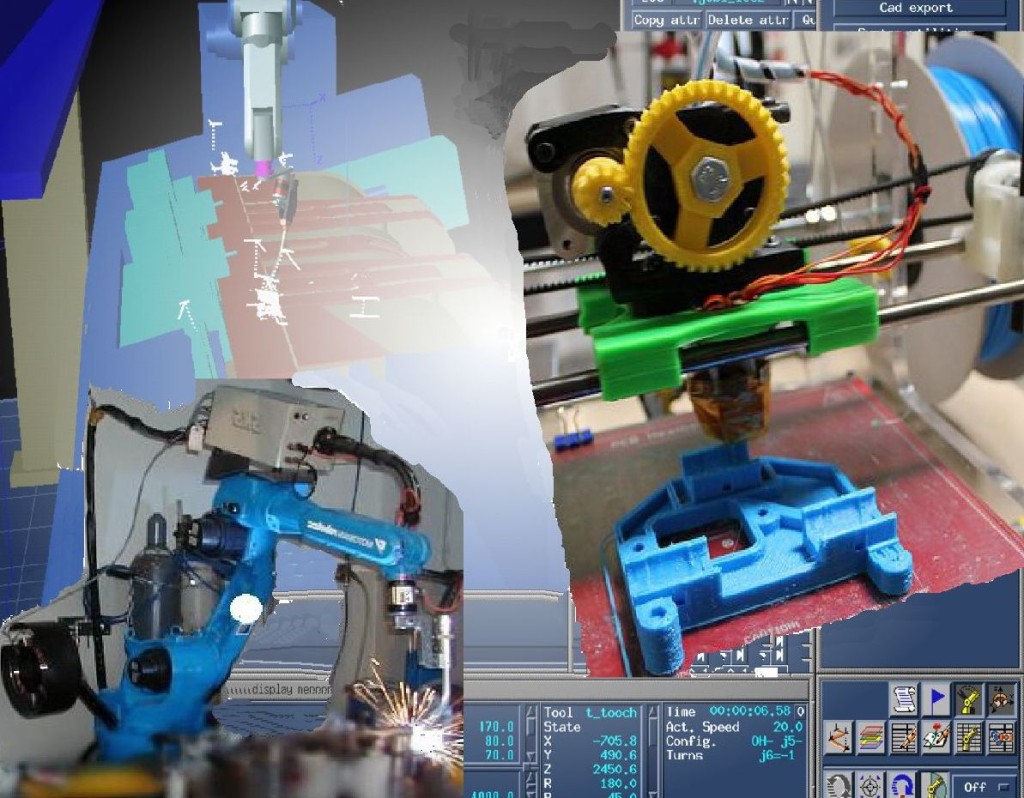

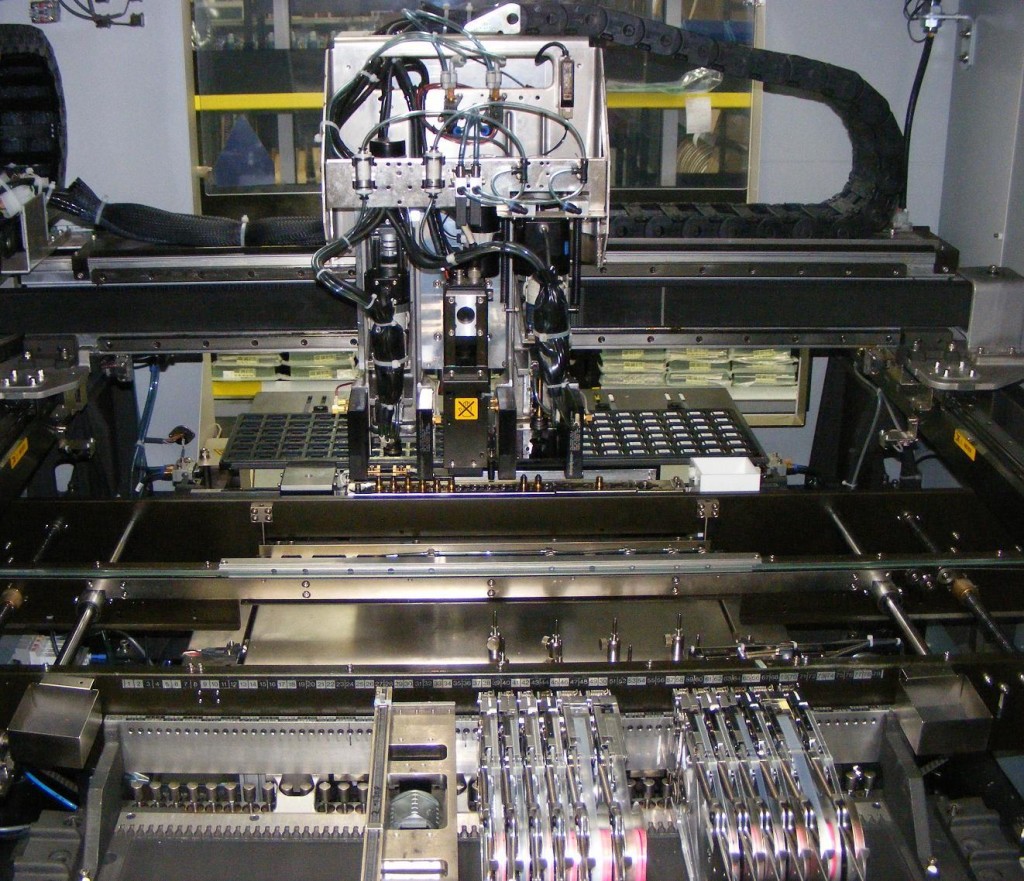

Picture by Joe Bain-Car Crash

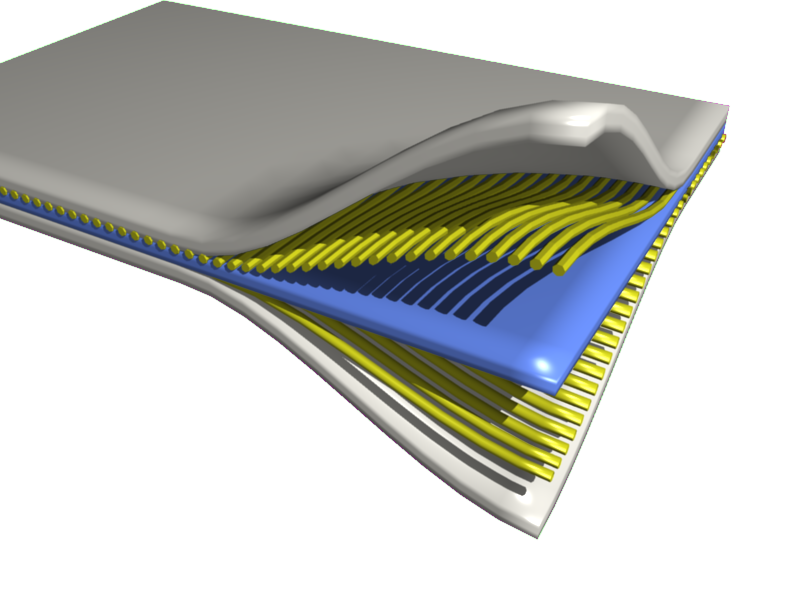

As manufacturers we are attracted to the advantages of processing plastics. Most of the smoke and dirt associated with creating parts out of metal disappears. The lower processing temperatures of plastics opens the door for robotic “lights out” plants. The big disadvantage is that plastics do not have an endurance limit. When you wish to buy a car that has a 11.5 year average operating life, you hope that it is made out of materials that can withstand the millions of imposed stress cycles that it will see during that life. The cars that are on the road today have skeletons that are mostly made of steel. Steel has an endurance limit. It is possible to apply stresses infinitely below a certain value without damaging the part. Having just replaced a plastic rear door handle, I can report first hand that it is just a matter of time before the plastic car parts are operated beyond their life. Having started my career as a suspension design engineer, I suspect that the recent crop of record breaking recalls, such as the Jeep suspension recall, are just the the vanguard of the flood.

The average age of US owner occupied housing is 34 years. About one third of that housing is 40 to 70 years old. Fortunately, much of the pressurized plumbing in the oldest housing is steel. Aside from the tendency to rust, it will not fail due to the contained pressure. We have grown accustomed to the reliability of the copper plumbing in the majority of our housing. In my experience it is not 100% free of leaks, but they are rare. Plastic plumbing is the most common material for new construction today. In normal chicken and egg fashion we will not know which of the various plastics used in the latest plumbing will have the expected 70 year life until the time has past. Due to the fact that I am currently recovering from a complete separation of a plastic connection within a five year old sink faucet, I can confidently predict that some evolution of design and material is still required. (I witnessed a wide open pipe making a flood like this picture)

We normally shut off the main water valve to our house when we are out of town. This is a good thing in that the plastic ice maker feed line leaked upon re-pressurization the last time we returned. I wonder if there is an emerging market for an automatic water shut off valve to prevent leaks from going undetected while the home is unoccupied?