It doesn’t look like a robot. It doesn’t even look like a vacuum. As one of the early Cobots it could safely work side by side with humans without danger. Cats — We are less sure about them, based on some funny Youtube video showing how they react to Roomba vacuums. https://www.youtube.com/watch?v=mk4XB2wZqF4 This early cobot spawned a few commercial derivatives to tackle what my wife’s grandmother called uphill work. This is work like laundry that you finish this week, just in time to start again at the beginning next week. As a teenager I did some of that running an industrial floor scrubber for my aunt’s janitorial business. No matter how good a job you did cleaning the floor one night, the floor started just as dirty the next night.

T5 walk-behind floor scrubber by Tennant (left) and HydroBot floor scrubbing robot by Intellibot Robotics picture by Z22

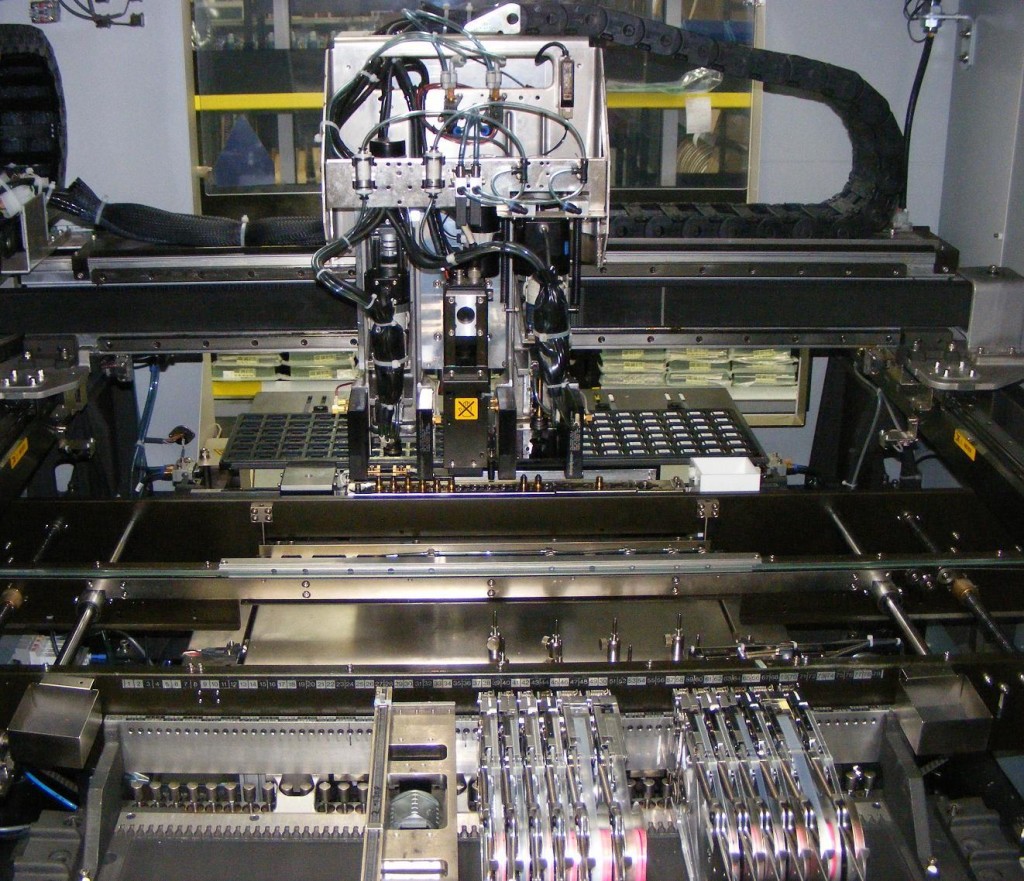

It could be argued that the first versions of AGVs were not full robots because they simply tracked a wire buried in the floor. Evolved AGVs such as the Kiva robots that Amazon uses to accomplish same day delivery are full Cobots. Even though Amazon got a jump on the rest of the industry by the strategic purchase of Kiva, competition is beginning to emerge http://netonomy.net/2015/04/29/three-robots-that-will-change-ecommerce/. In much the same fashion that Roomba came in at the fringe, the need for a robot that could work side by side with a human ushered in the gantry style robot. The gantry has predictable X Y Z motions with hard end stops which eliminates the need for the bullet proof cage. The space advantage of a Cobot makes it my favorite choice when implementing an automotive cell. I am particularly proud of a jet engine turbine blade inspection machine that uses ultrasonics to detect cracked blades before they fail.Honda thinks the same way and I was not surprised when I saw a gantry robot carrying cylinder heads between machining stations at their Alabama assembly plant. The electronics industry is faced with the same issues of mixing automated and human assembly. They also have adopted gantry style cobots for their surface mount technology

Internals of a Juki KE2010L 4 head pick and place surface mount machine. the machine is used to place electronic components that are soldered to the face of a printed circuit board rather than having leads go through holes in the board. The machine is loaded with standard 8″ reels on mechanical feeders (front right) and a tray of QFP microprocessors (rear center) Picture by Peripitus

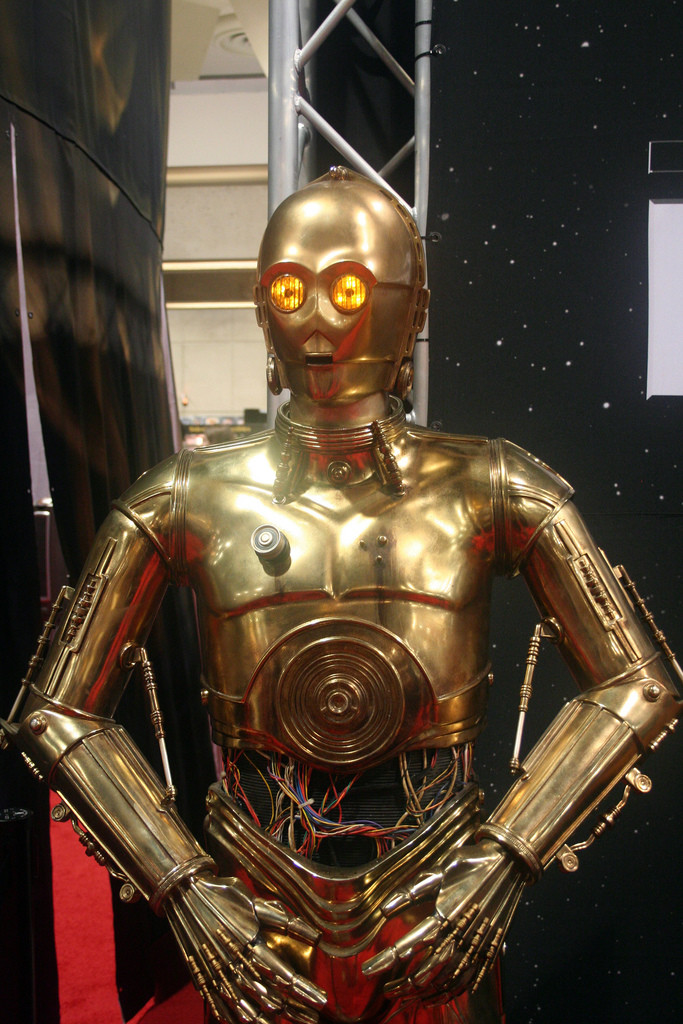

Technology will advance to the point where we can build a C3P0 Cobot. It will happen as a step by step evolution. We are on our way. Currently in the lab are vision, tactile and capacitive skin collision sensors which will become affordable.