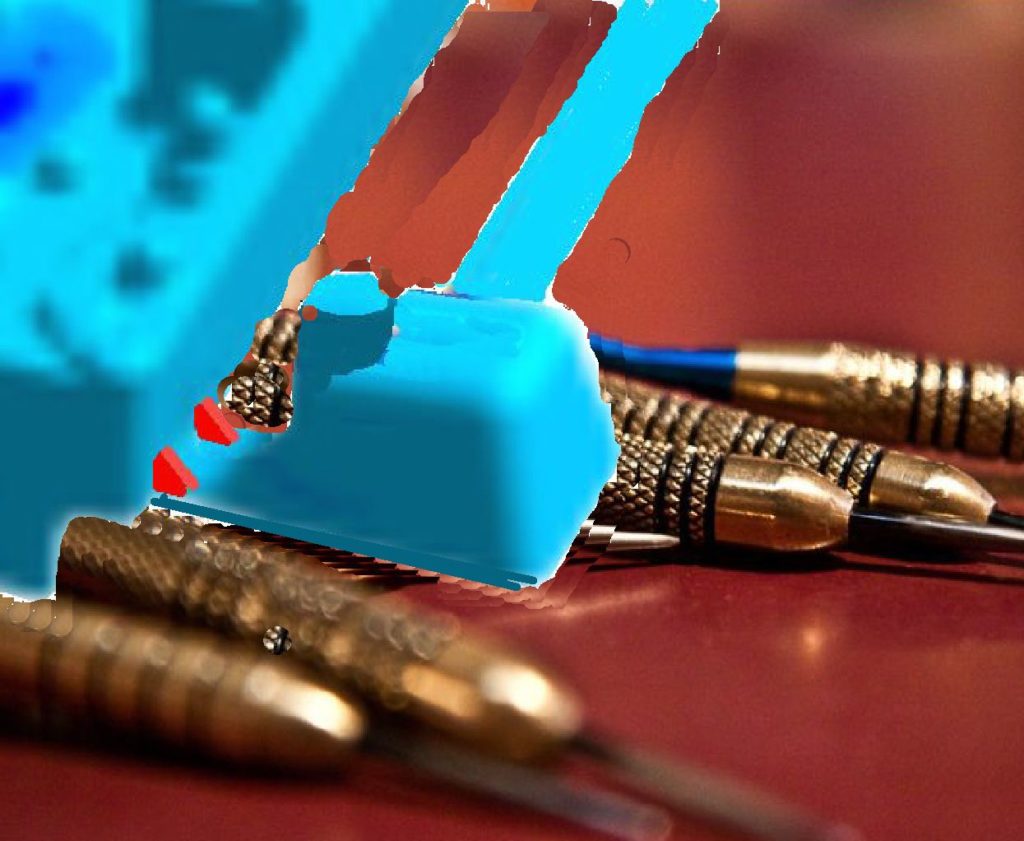

Die Casting would be a lot easier if there were a single trick to making a die run profitably. My experience is opposite to that. It takes a whole bunch of details done near optimum to make a smooth running job. A set of darts on a overflow transfer is just one example. At one shot per minute it is really easy to fill a pit or make a mess over the floor if a overflow wants to break off. Yes, thickening the transfer will keep it attached at the expense of trim break in and die spitting. A better solution is a pair of .7mm thick darts at either end of the transfer, This creates a structural channel cross section that cantilevers the overflow until it is time to trim. For those who don’t believe me, go back to sweeping overflows off the floor.