Packaged 3D

Life could be a box of chocolates. The challenge in this era of mass customization is that the assortment of flavors that we want to buy changes with the wind. If you look at the picture carefully you will discover that the pockets match the shape of the chocolates. This means that if you want to change the assortment you require a new mold. The associates filling the box also find it hard to adapt to continuously and randomly changing customer order. It would also be helpful if the vacuum molded tray had some visual management labels to guide in the fulfillment activity.

Enter 3D printing. Invisalign pioneered the use of 3D printed molds to shape plastic sheet.Since every retainer created is different, the 3D printing process also molds into each item identification information. Why did Invisalign choose plastic sheet?

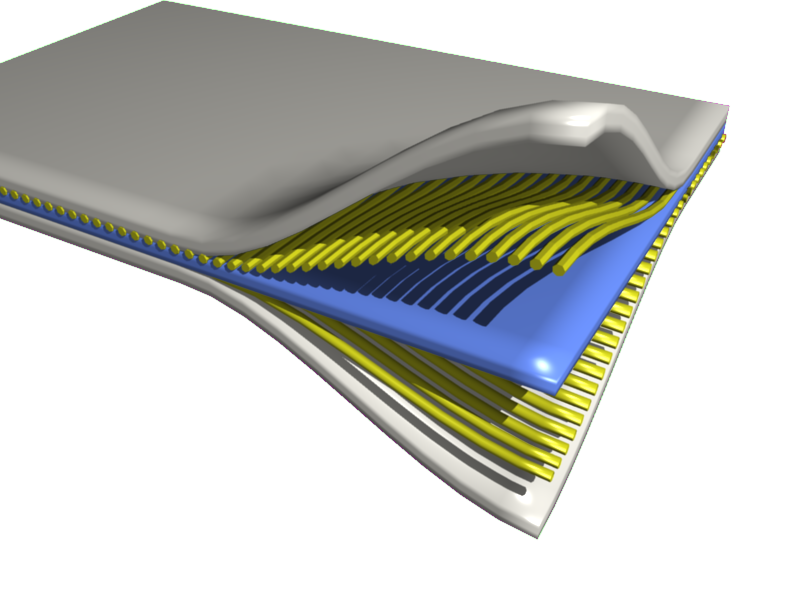

From the earliest blacksmiths shaping swords, the engineering community has discovered that it is possible to increase material strength if the application does not need the high strength in all directions. The bio-compatible plastic used by Invisalign actually works as a retainer, whereas the 3D printed plastic used to make the mold is too brittle and you would not catch me sticking it in my mouth because it still contains active plastic precursors. Other plastic composite sheet can be even stronger because reinforcing fibers can be laminated into the mix For example pneumatic car tires must have embedded fiber reinforcement to withstand the applied forces. Airplane manufacture is a logistic nightmare. About 100,000 parts must be manufactured and gathered together in the right order to make a plane come together. The Boeing engineers joke that FISH (first in still here) has replaced FIFO (first in first out) as their accounting system. Boeing in their Moonshine Project determined that staged delivery to the assembly floor is more that sending the parts. The parts themselves are useless without the matching tools to install them. In their historic system workers spent much of their working day traveling back and forth to the tool cabinets around the working area. As we gain engineering control, the implementation of molded tool trays on 3d printed molds is an effective shadow board so that it becomes possible visually to determine in the warehouse that all of the required tools are sent with each cart of parts.

Some of the solution for the shortage in transportation capacity has to come from efficiency. It would be easier if the marketplace didn’t want mass customization at the same time. I can picture us evolving to 3D print to order shipping trays so that full density skid size loads can be assembled upstream enabling fast loading and less unprofitable empty space in transit.