Extracting castings is probably more difficult than extracting teeth. At least the equipment cost is greater. Teeth are not hot enough to burn you when they are pulled. Dentists do not need to continuously extract teeth as a one a minute rate.

Most high pressure aluminum castings are either removed from the helper or operator side of the casting machine. (I have seen a few dropped out the bottom- especially 3 plate die gates ) In the simplest form an operator grabs the part and runner with a plier. The hot part is usually moved to an operator platform table. In many operations the runner is hammered off on that table. Hot runners can be recycled directly into the holding furnace. Clever die cast plants use hooks on top ejector pins to hold the casting after it is ejected. This saves having to synchronize pushing the eject button with the grab. Manual extract of castings can be used on all sizes of machines. My latest 4000 ton installation has a knuckle arm run by the operator to grab the castings and runner and transport them to the operator platform table. Safety standards dictate the use mechanical transport devices when the weight being moved is over 35 lbs (16 kg). Knuckle arms are unpowered such that no robot safety enclosure is required.

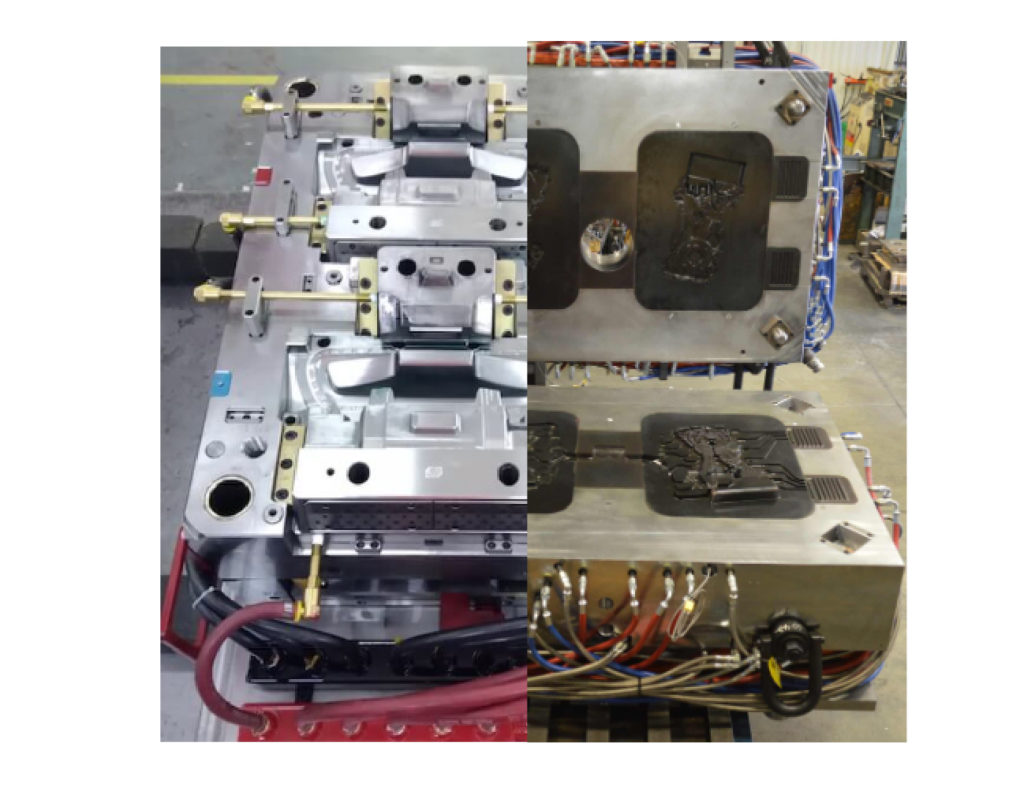

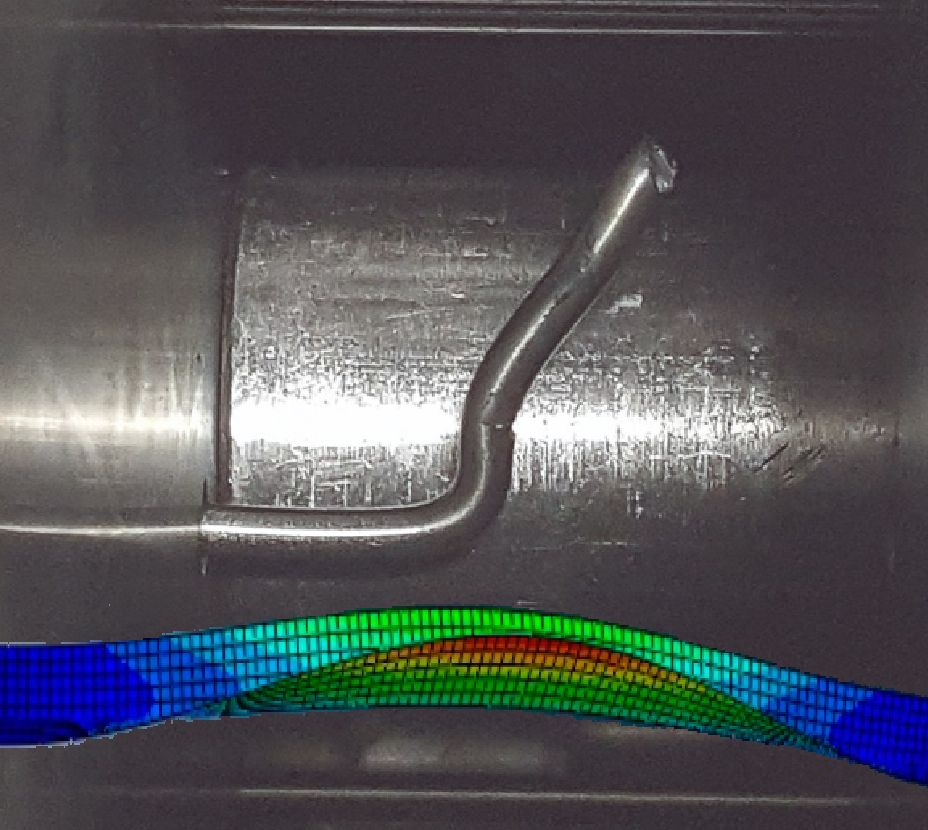

Automated extraction can be either helper or operator side. Helper side extractors keep the hot castings separated from the operator. Horizontal robot transport bases are pre-engineered building block. Helper side extractors require more horizontal motion because it is the normal practice to extend long slides out the helper side.

When I set up an operator side extractor, casting can be manually extracted with the extractor shut off. This is necessary for difficult jobs that have to be started using manual spray and /or die slick. (Many times an automatic spray can take over running a difficult job once it is started) My operator side extractors reach through a window in the safety door so it remains closed. This is a cycle time saving. High speed extractors like the Rimrock 320 that I invented with them can pull a casting in 5 seconds total cycle time contribution.