I always find a good dish of spaghetti attractive. My wife buys our favourite tomatopasta sauce and adds in the meatballs. In all the years of eating spaghetti I have never counted the number of strands on my dish. Usually they are eaten before that is possible. I cannot imagine having to number each of the strands of spaghetti that are on my dinner plate. Numbering the hoses feeding a gigacasting die is just the beginning of utilizing them to achieve the correct temperature distribution in a die

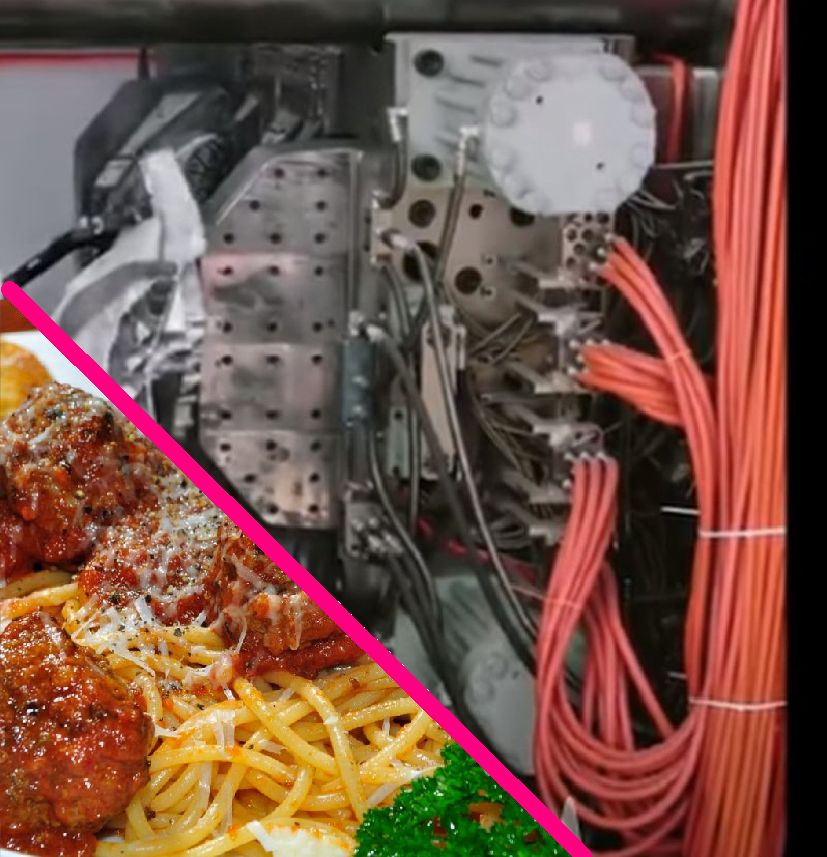

Now we have gigacasting dies. As you can see in the picture more than 100 hoses are connected to each half of the die. The “spaghetti” gets worse when you realize that each hose feeding the die is looped into 3 to 7 thermal passages within the die. I am not surprised. Elon said that a gigacasting combined 70 pieces into one. The thermal passages you would use to make 70 individual casting dies got incorporated into a single die. Even the huge slides used to create the rear wheel housings have a large numbers of percolator style thermal passages in the fingers that form the rear rail section.

Die casting dies that are at room temperature do not produce good castings. Die preheating is used to avoid scrapping up to 100 castings to bring the die up to steady state operating temperature. Gigacasting dies weigh 100,000 Kg. Using the 490 J/Kg C heat capacity of steel, 160 Kw Hr of power input is needed to increase the die insert temperature to 100C and raise the holder temperature to 75C assuming no losses. Actual heat input requirements are double that factoring in convection losses and platen heating.

A pair of 90 KW hot oil Thermal Control Units (TCU) happily preheat a gigacasting die for prototyping if left on overnight. When a long preheat period is available other issues like having enough heat transfer passage length are not a concern. Gigacasting integrated into an assembly plant is another issue. 2 hours of assembly plant shutdown waiting for a die to preheat is an eternity, I suspect that the hose “spaghetti” we see is to enable the use of 5 additional 48KW TCU’s to reduce the preheat time to under an hour.