The introduction of new electrical users such as electric cars are keeping electrical rates on the radar screen. I tend to agree with Elon Musk that this will cause the electric utility industry to expand their infrastructure. Usually changes like this are accompanied with an increase in rates. Most businesses will be pressured to consider actions that will control the cost increase. Reducing demand charges is one of the best ways to continue to obtain the energy needed at a more affordable cost.

“Saving Money by Understanding Demand Charges on Your Electric Bill” — This Tech Tip explains demand charges, how they are calculated, why we need to monitor them, and what we can do to lower them. Demand–related charges usually represent 30 to 70 percent of most commercial customers’ electric bills. Electrical demand in some parts of the Nation stretched the capabilities of electrical generating and transmission systems during the summer of 1999″ Dave Dieziger, Project Leader US Department of Agriculture

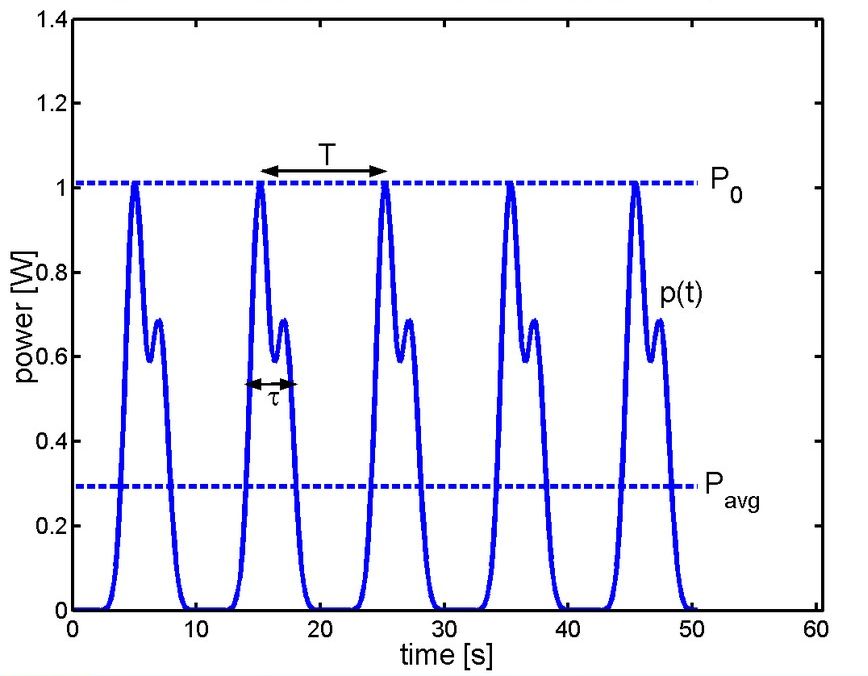

Many process cells have a spike load which is much higher than the average load. This fact opens the door for reducing demand charges

Leveling the peaks- The size of the wires (and generating equipment) is directly related to the maximum demand that your equipment requires. Historically we had few affordable options for reducing the peak. With the advance of modern computerized electronics, better options exist. In a recent installation a soft start on a 200HP motor proved very cost effective.  Even discounting the future energy saving, it was possible to cover the extra cost simply by reducing the size of the wires feeding the machine. It is interesting that more than the power company is concerned with wire size.

Even discounting the future energy saving, it was possible to cover the extra cost simply by reducing the size of the wires feeding the machine. It is interesting that more than the power company is concerned with wire size.

Automation is becoming a popular business survival technique. Virtually all automation requires electric power. The wires feeding an existing cell (or transformer feeding the plant) may not be sized to support added automation or robots and handle the spike loads. In many cases it is cost effective to reprogram the PLC computer running the cell to level out the spikes. This frees amperage to run the added automation. In the die cast rebuild I accomplished last year this turned out to be nothing more than adding program steps to insure that all users did not grab power simultaneously. 100 amps out of 450 amps became available for auxiliaries. Yes a slight increase in cycle time for this change occurred. After I was done, this cell in total had a quicker total cycle time because I overlapped other actions.

Filling in the valleys – We are seeing process controllers, software, tooling and equipment evolve to the next technology level. In mold making this can be disruptive. Historically we we pleased when the cutter path software could simply create the shapes. We used large margins to insure that power demand did not exceed the supply. Most of the time the mill motors were barely off of their minimum power.

Recent advances in milling cutters and driving software have made it possible to stay at 70% spindle power instead of 10%. The reduction in time from 3 days to 1 for removing the 6000 lbs of chips to create a mold holder is disruptive to the CNC build marketplace. The CNC machine builders will have to adjust to selling less machines.

Storing energy – Many hydraulic powered machines use accumulators to store energy and balance demand. The original equipment builders in many cases did not work with the end user to optimize this storage.

My recent rebuild at Canadatum showed that it is possible to level the power usage of the machine by paying careful attention to the timing of the recharge.

Combined together engineered power management has can knock 10% or more off of the power bill.