I learned die casting from a fanatic. He honed his skill to the point where he was able to achieve unbelievabe die life. In the five years that I worked with him, he never welded a casting die surface (introducing heat check) that contacted molten aluminum. I have to take responsibility for the one time that it happened. The OEM engineering group forced us to implement a panic shape change. Welding the die was the only option to meet timing. Because of his fanaticism we regulary achieved die lives up to 500,000 shots on heat check sensitive parts like transmission stators.

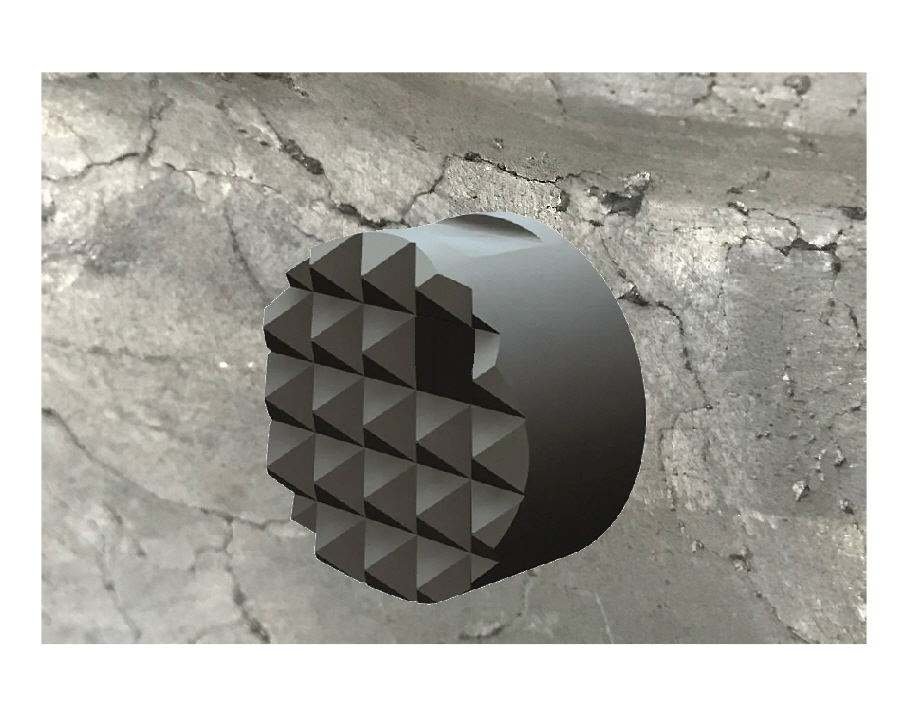

The die casting industry is learning how to economically make the emerging structural castings. These castings are made from alloys that have a hotter casting temperature. Higher casting metal temperatures result in more heat check. Heat check begins in as little as 5000 shots. In most cases it is a good practice to use toothed machining locators The teeth ignore some heat check and improve located consistancy. When the volume dictates multiple machining nests, removing a tooth makes it possible to mark the processed casting to indentify which nest was used.