Take Off

Every time I visit an airport I marvel that it is possible to lift 100 tons of metal into the air. As an engineer I also know that in most cases the engines are operated during take off at 110% of the power output that they can deliver on a continuous basis. This extra power is needed to accelerate the plane to flying speed in a reasonable runway length. When I fly it is comforting to know that this is not the first time that the plane successfully managed a take off. I am also not surprised that flegling aircraft are tested on much longer runways so that the pilot can choose to abort and try again if the indicators are not favorable.

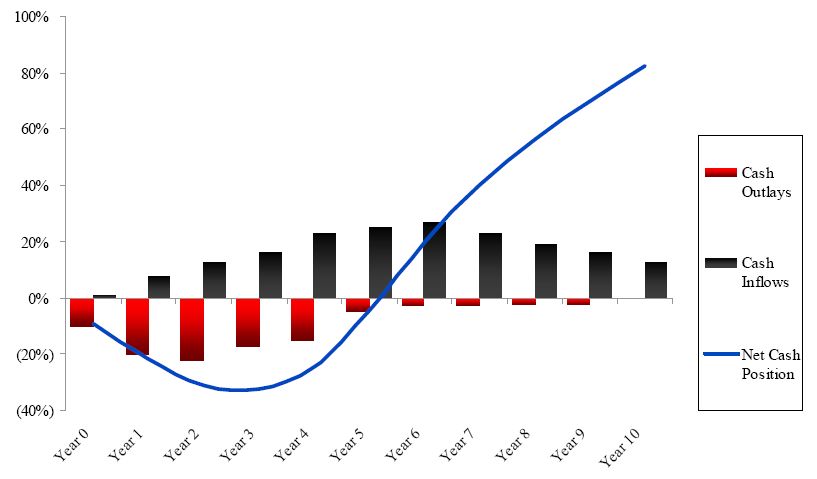

The same approach is used to get a business to take off. Yes, it is going to take much more effort to get it started than will be expended keeping it going. As “The Lean Start-up” teaches us, we will need to abort some take off attempts and pivot to new strategies. This is why venture capitalist describe the cash flow of a start-up business using a J Curve. Most successful start-up companies will require input capital to fund these aborted take off attempts

Even though the concepts taught in “The Lean Start-up” were honed in the software community they have relevance within the manufacturing community. In manufacturing it is less possible to obtain the same rapid customer input and testing that is enjoyed by software creators. Just because it might not be possible to evolve as fast, improving time to market has major benefits. The advent of tools like 3D printing and computerized finite element testing have made it possible to substantially shorten the time to pivot to more acceptable customer offerings. Historically the 3D CAD designers could work at a leisurely pace because they were faster than the down stream tooling builders. In the emerging new economy the leaders have discovered that they can get a jump on their competition by putting the systems in place to accelerate the creation of 3D CAD definition.