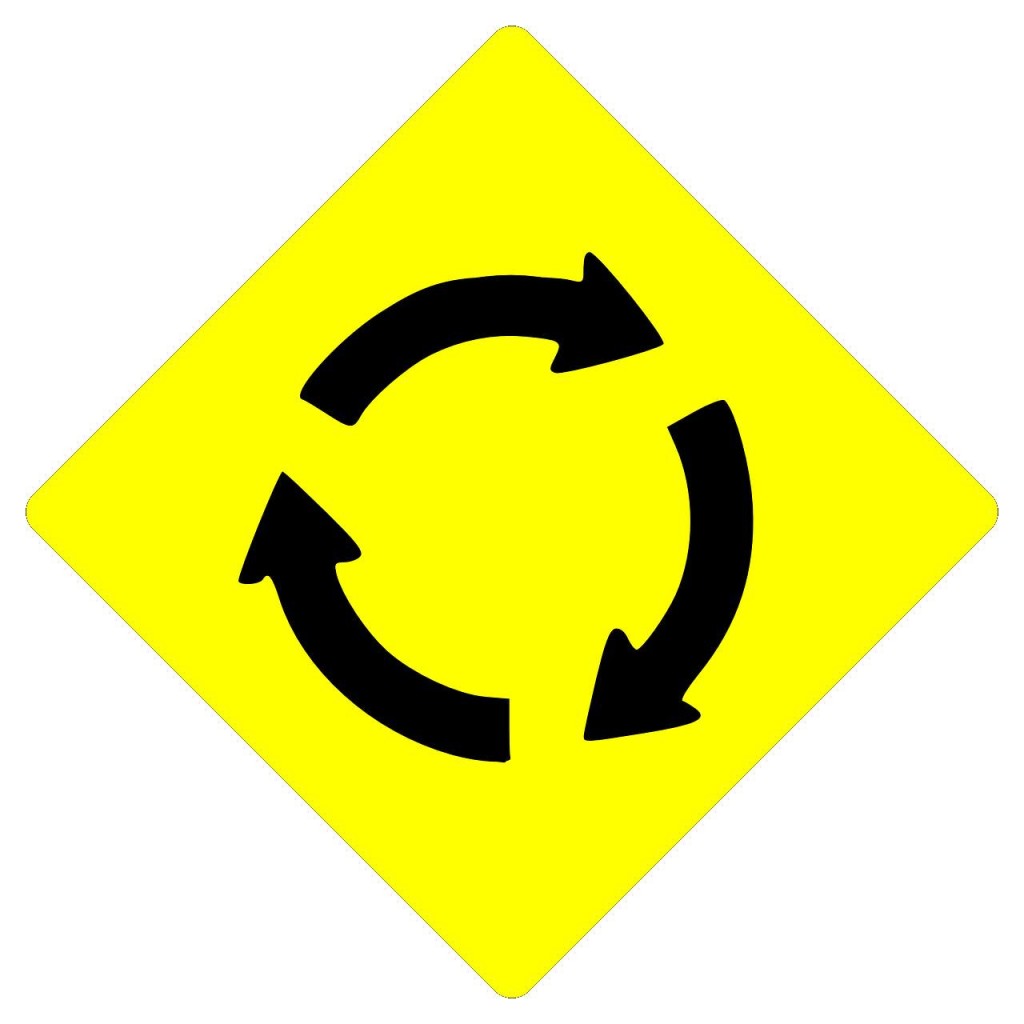

Turning Circle

I discovered the difference between turning circle and turning radius on my first trip to Ireland. The landscape of Ireland is largely made up of exposed bedrock. The roads snake across the ground in continuous curves because blasting is very expensive. When you travel around what they call an acute bend your mirrors stick out. Even though I was driving a rental car with a short wheelbase that had a tight turning radius, it was the turning circle that really mattered. I discovered that European cars have collapsing side mirrors. You can guess how I discovered that fact. Passing a car going the opposite direction tests whether the entire vehicle is out of the way. The saving grace of being a Irish tourist was that I did not have to drive a bus. The long wheel base of a vehicle like a bus makes both the turning radius and turning circle much larger.

Designing a vehicle for use in a warehouse brought back the memories of driving in Ireland. The aisles are narrow and the corners at the end of the racks are sharp. The theoretical radius path of the vehicle on the floor makes little difference if the corners of the vehicle stick out enough to knock the shelves over. Yes, longer wheelbase vehicles are harder to drive in a confined space. However we all know that more goods can be carried on a larger vehicle. Attention to detail is what makes the difference. Chamfering the corners of a longer wheelbase vehicle can result in the same turning circle that a shorter wheelbase vehicle can achieve. In today’s lean economy, we are all looking for the extra percentage improvements that

come from paying attention to detail.

Engineers think about the difference between a turning radius and a turning circle. The actual industrial vehicle users are only concerned about their ability to drive through a tightly packed warehouse without hitting the shelving or damaging the goods that they are carrying. At the end of the day lean is all about safely moving more goods each trip.