Lean for the Masses

Enter the computer revolution. Globe spanning telecommunications, bring vast quantities of information to our door. A few individuals have discovered ways to leverage this advancement into serious income. The cash flow has also attracted modern day pirates that apply their effort into gaming the system. Many of the innovators have reacted to pirate attacks by innovating further. The rest of us just see chaos.

This will settle out. While I was in college a new generation of calculator came out about every 6 months. We all progressed from a simple floating point machine to a full

scientific calculator. The interesting point is the process stopped. My current calculator is as powerful as the one I had leaving college. As a more recent example Open Office as a commodity software has heralded the maturing of the Microsoft office suite.

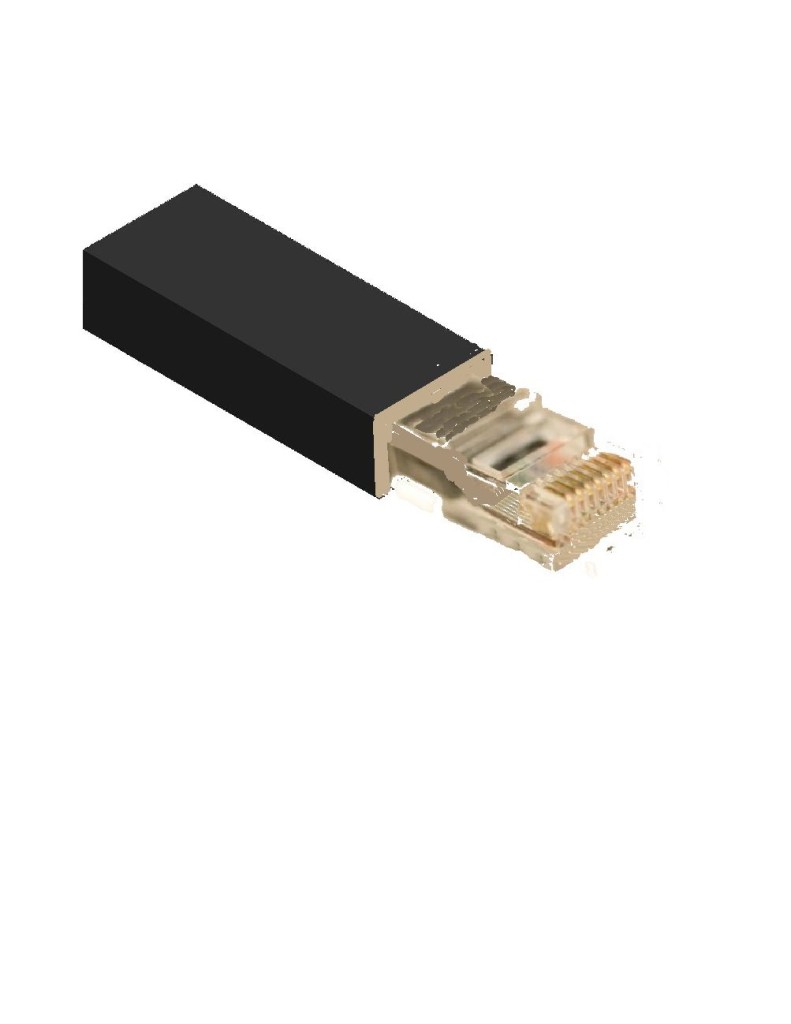

The recent advancements in 16mm low power processors will open the door to combining

memory and computing power onto a single stick. This advancement will close a popular

door used by pirates and enable the monetization of the effort required to create custom lean applications. I suspect that some of the recent wealth gap increase is related to the lack of a secure vehicle for the people who have discovered new lean wealth creating methods to sell that knowledge to the masses