My Grandfather was an excellent carpenter. I inherited his Audels handbooks on how to create various wooden structures. It is fascinating reading how to build a barn without using nails. I doubt I will ever need to accomplish that task in my lifetime. My dad was an engineer before me. I also inherited

his engineering reference books and his slide rule. He did his best to pass the torch on to me, I do not foresee ever designing another oil refinery. Each generation has new challenges to undertake. Now that I have the torch, I must determine the best way to pass it on to the next generation. Fortunately I am not alone in wanting to transfer skill to the new generation.

Woody Flowers an MIT mechanical engineering professor also saw the need to pass the torch. He put together First Robotics as a tool for teaching high school students how to accomplish the engineering tasks associated with designing and building robots. His brilliance shows in that he made the journey fun for the participants, First Robotics has grown into a world wide competition that attracts aspiring engineers.

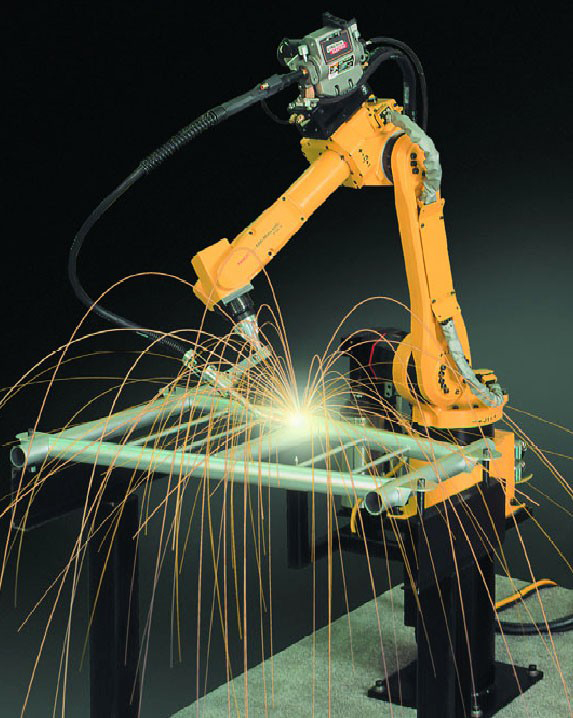

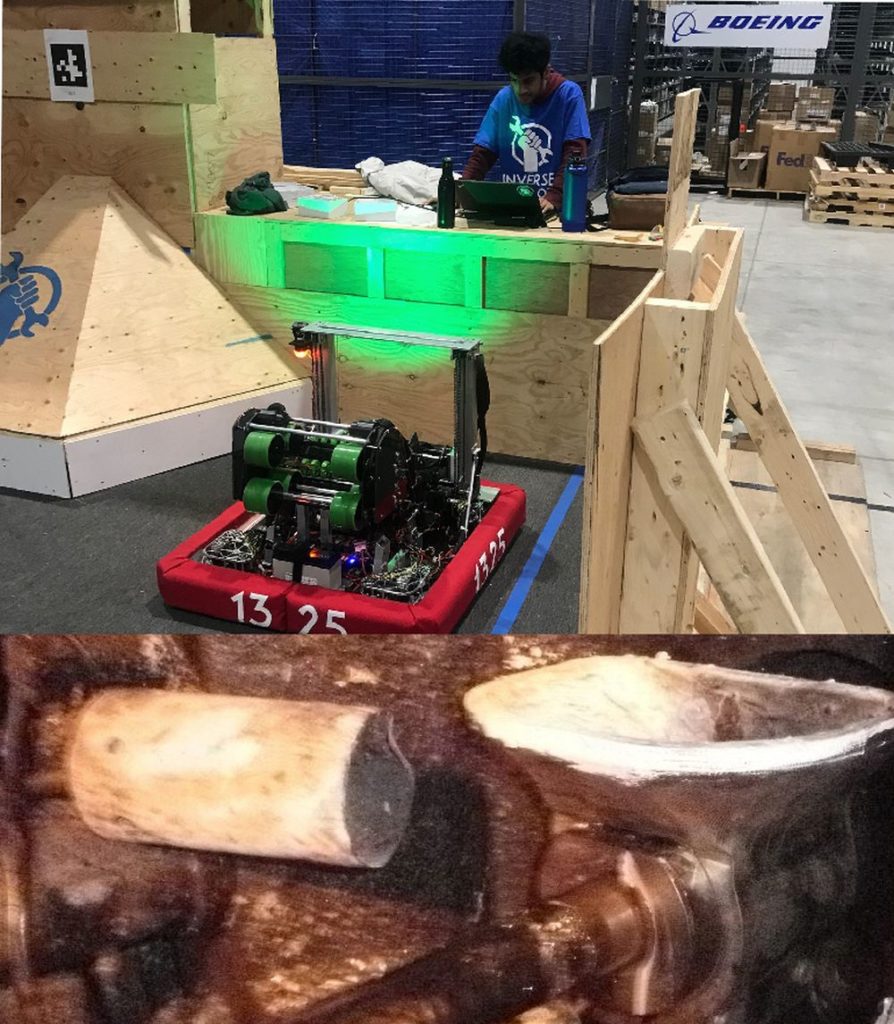

I volunteer mentoring a local team. Pictured is the robot that the students designed for this years competition. The alumni of our team have impressed a few of our industry sponsors who are equally concerned about passing the torch. The support of sponsors only improves the training we can impart

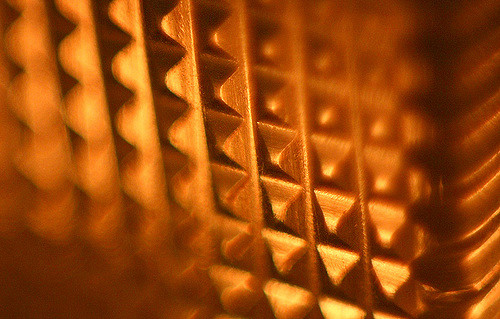

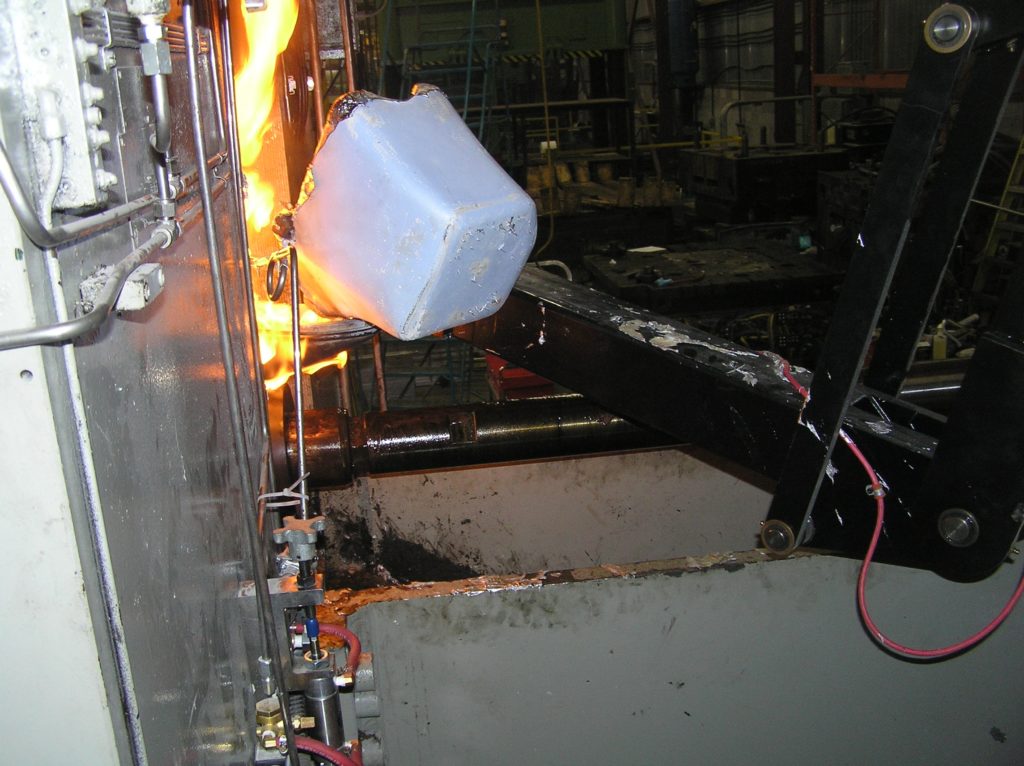

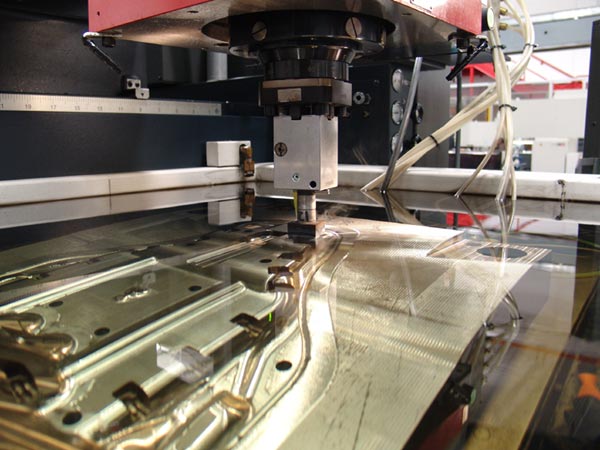

Die Casting has shrinking number of North American Companies that use the process. This is in spite of the rising amount of aluminum used in vehicle manufacturing. Some of my skills such as creating the 3D models for the new larger size torch heated funnels (launders) that are a part of the new Mega Casting cells are being taught to the students that invent the First Robotics competition robots. Otherwise the education system is reverting to saddling the graduating students with massive debt without the skills needed to repay it.