One two three four five six seven eight nine ten eleven… all the way to the 60 second rule. Coworkers think I am crazy when they hear me counting out loud to sixty. This is a success habit. I am impatient. Counting out loud keeps me from turning the power back on too soon. It is also a good training tool because people ask what I am doing.

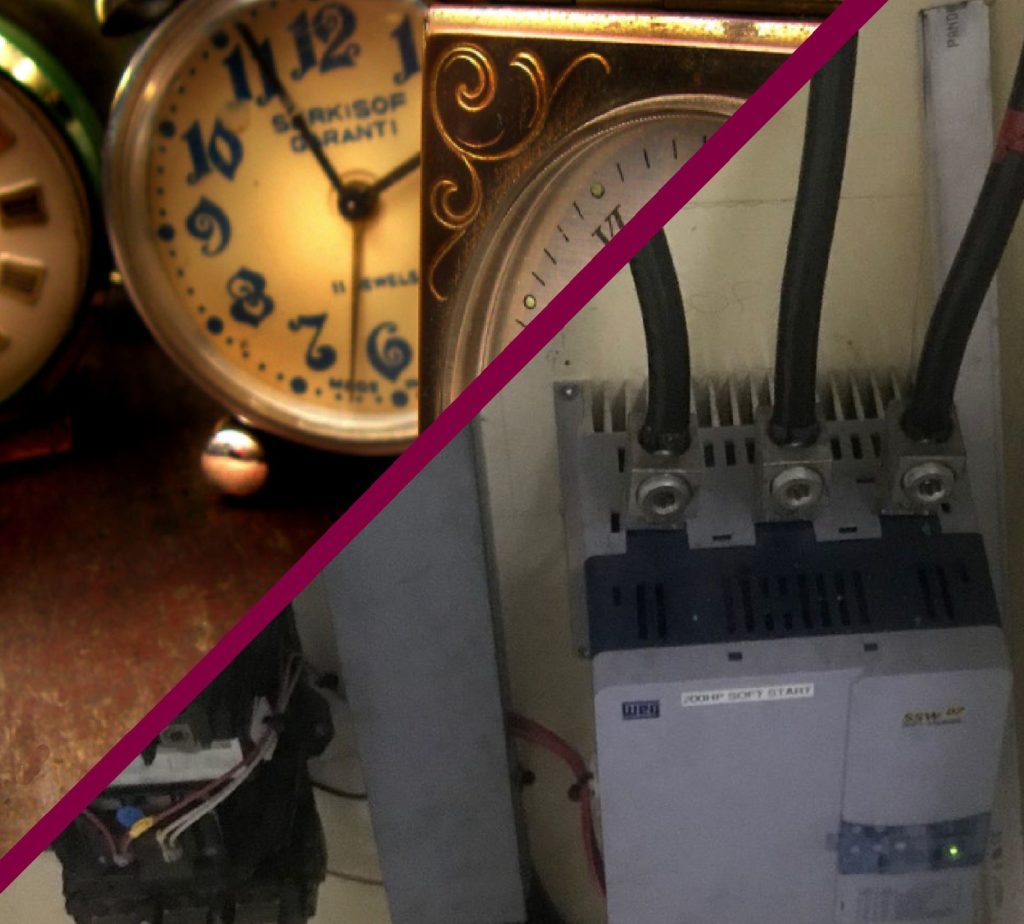

In our electronic age many of the controls are computer operated. I installed the pictured 200 amp motor soft start on my 3500 ton die cast machine because I wanted to free enough power to run oil heaters. Lightning strikes. About 12 times per year it hits the power grid within 5 miles of the die casting plant. Usually trips out this motor soft start computer with a fault code. Enter the 60 second rule. The soft start error happily resets if you leave it off for the 60 second rule. Also applies to the crane drives, the CNC machining centers, Gun drills, Just about every piece of equipment with an embedded computer. The residual power must drain to force a reboot. Count to 60 out loud before you call the service technician.