[/caption]

Most of us have learned how to ride a bicycle. It is pretty safe to say that riding hands free is unlikely initially. This is an unrealistic expectation. The balance and poise that it takes to ride hands free is developed with practice and experience. The hands free rider in the lead picture has many miles of experience under her belt. She is riding hands free without being on a smooth paved road.

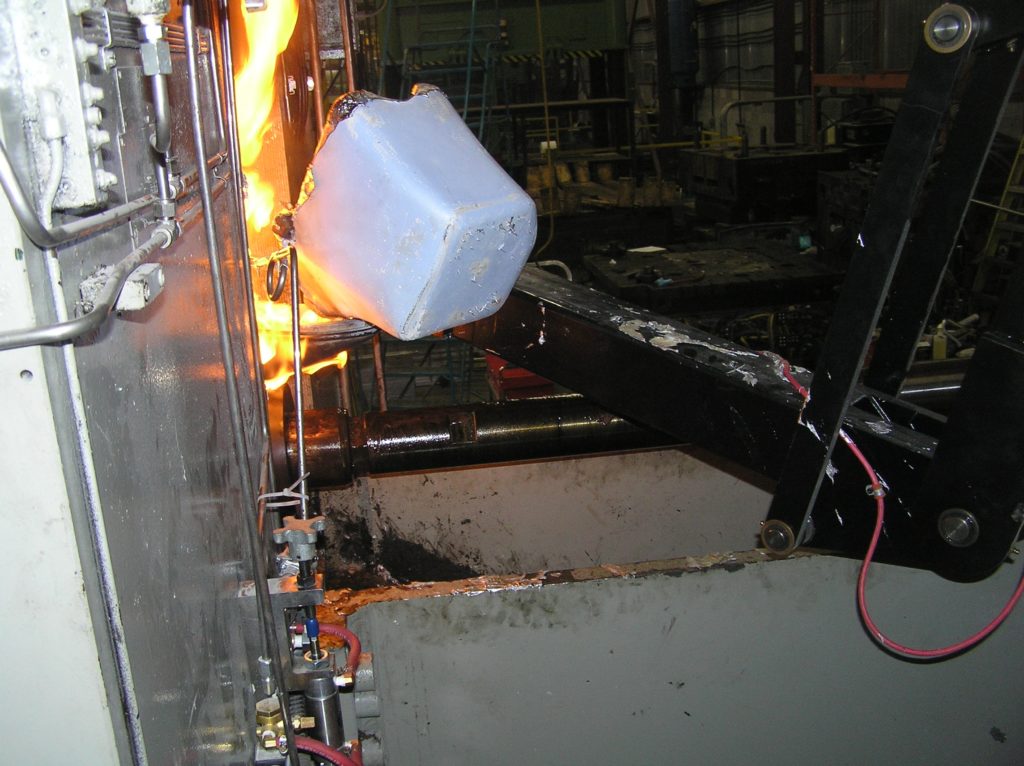

We would all like the automation that we install to operate like “hand free” bicycle riding. Like “hands free” bike riding, it is unrealistic to expect this level of results the day the equipment is turned on. Insanity also applies. Doing everything exactly the same and expecting the results to improve is the easiest way to prove that you are insane. Achieving “hands free” automation requires some degree of active improvement from the initial installation. I am currently commissioning a robot that delivers molten aluminum. The last time I achieved “hand free” simplicity on a molten metal transport robot, I had invested a couple of years of planning and implementing small improvements. It was necessary to add all of the intelligence of a human operator to the program such that the robot knows what to do for the majority of non standard events. Silly little changes such as improving the synchronization signals make all the difference.