Automation is more than robots. Use the power of computers to buy back more of your life. The computers in my car create an IRS compliant mileage log. I no longer spend three days of Christmas week on the task

Tag Archives: automation

Hands Free

[/caption]

Most of us have learned how to ride a bicycle. It is pretty safe to say that riding hands free is unlikely initially. This is an unrealistic expectation. The balance and poise that it takes to ride hands free is developed with practice and experience. The hands free rider in the lead picture has many miles of experience under her belt. She is riding hands free without being on a smooth paved road.

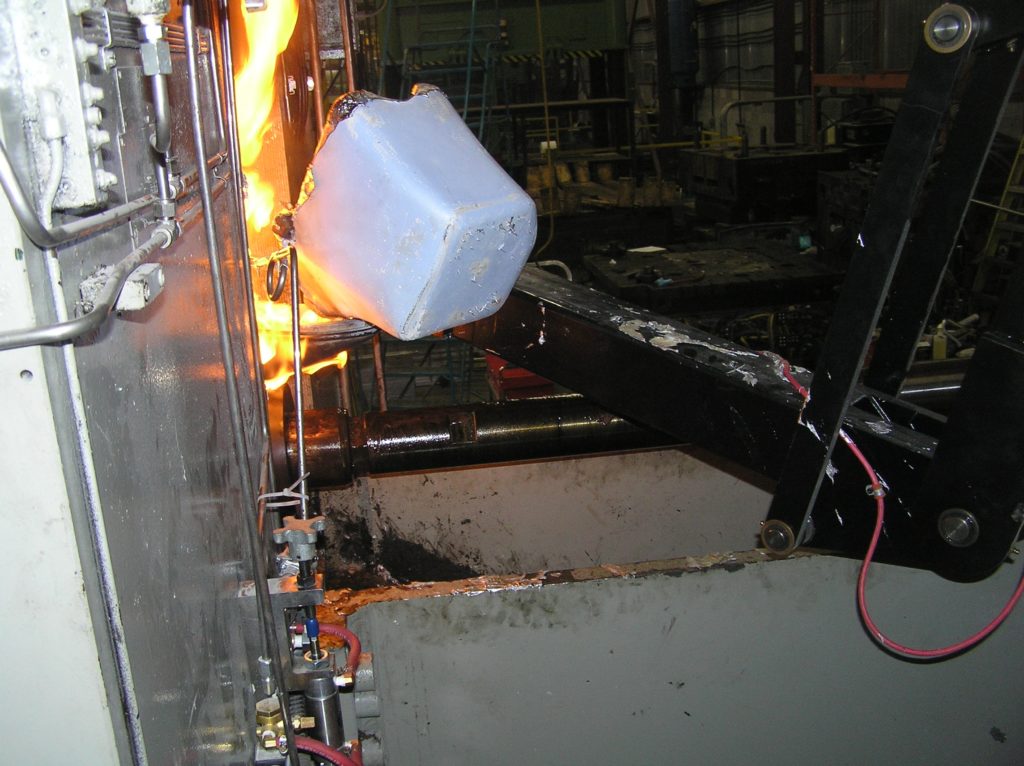

We would all like the automation that we install to operate like “hand free” bicycle riding. Like “hands free” bike riding, it is unrealistic to expect this level of results the day the equipment is turned on. Insanity also applies. Doing everything exactly the same and expecting the results to improve is the easiest way to prove that you are insane. Achieving “hands free” automation requires some degree of active improvement from the initial installation. I am currently commissioning a robot that delivers molten aluminum. The last time I achieved “hand free” simplicity on a molten metal transport robot, I had invested a couple of years of planning and implementing small improvements. It was necessary to add all of the intelligence of a human operator to the program such that the robot knows what to do for the majority of non standard events. Silly little changes such as improving the synchronization signals make all the difference.

Warm and Fuzzy

We all know the drill ” Thank you for calling Modern Company. If you know your party’s extension please dial it now. For sales dial 101, for service dial 102, for HR dial 103, for accounts receivable dial 104, for shipping dial 105, for scheduling dial 106 —- if you wish to hear the options again press 1″ Usually none of the listed extensions match our needs, so we pick one in desperation only to hear a recorded message “Your call is important to us, please call back when our operators are not busy.”

In today’s lean world, nobody has time to sit at their desk waiting for the phone to ring. If you look at the sea of desks they are mostly unoccupied. Many of the players are simultaneously sitting in teleconferences while answering the daily bombardment of 2 to 300 internal e-mails. This overload is unsustainable and the pendulum will swing back to add new controls. Back in era of large companies, the chain of command was expected to correctly filter the information flow. Sending communication to higher than your boss’s boss was not permitted.

It would be nice to think that an instruction manual would be sufficient to accomplish a simple installation like a computer display screen. In the industrial automation arena, equipment is expected to live 7 years with first rebuild giving another 7 years. When you are matching a new display screen to equipment and controls that are more than 10 years old, a generation miss match occurs. Usually a live local technician with many years experience is needed to resolve the problems, especially if the set-up is complicated by having a defective replacement display screen to start with. This is why we pay a premium to buy industrial display screens because warm and fuzzy help is usually needed to get the repair done. Even good live help, last week we lost three days of production sorting out the replacement of a dead computer display screen.

This is an opportunity that start-up companies can use to grow. Most customers want a warm and fussy feeling and react favorably when they are serviced by knowledgeable people who are not remotely located in a call center. The UX (User Experience) movement is all about having your development staff interact with a representative group of users. As we performed the www.mileagetrakker.com beta test we personally got to know all of the beta testers. Since most people learn by interacting with other people, it was natural for the www.mileagetrakker.com beta testers to acquire the knowledge that they needed. As we scale beyond the beta phase, we continue to test which of the introductory activities can be automated on the website and which training and set-up actions require personal involvement by the sales staff. Even though is is possible to accomplish all of the actions needed to acquire a Mileage Trakker device by interacting with the website, the vast majority will join us due to the activity of the sales staff.

The new battle ground in the marketplace will be establishing the correct balance between efficient computerized automation and warm and fuzzy human support. Monopoly power can force customers to fight with faceless computerized non service, but this jeopardizes the continuation of the company. The pendulum will swing back to creating new employment roles for people.

Lean Automation

I have to admit that many years of installing robots to reduce labor has blinded me into thinking of automation as robots to be installed. This matched the marketplace because the $200,000 robots morphed into $50,000 robots opening the door for new applications with each price drop. Shop floor manufacturing cost which was $.50 of every sales dollar in the 1950’s has steadily declined to $.20 of every sales dollar today. Since 80% of the current business costs are not on the manufacturing floor, it is not surprising that the best opportunities for reducing cost by automating are no longer on the shop floor.

It would be naive to claim that no automating activity has occurred off the shop floor. The PC, then smart phone revolutions, have brought the efficiency of software to our fingertips. We would not even consider typing and mailing a letter anymore. PC Office suite software is now available as “free” open source downloads. The more recent smartphone market is equally mature. Even as early as 2010, 90% of the smart phone apps sold less than 100,000 copies, which suggests that they failed to cover their development costs.

The 80% share of business cost off the shop floor shows that the current opportunities are still away from the shop floor. The developers agree and the latest excitement is centered around innovations that combine software and hardware. This is consistent with what I am seeing. Somewhere in the future your cars will have enough connectivity and spare computers or your cell phone will have enough battery capacity to handle extra tasks. In the short term dedicated devices such as the mileage trakker http://mileagetrakker.com that I market are good examples of the latest trend. Business people who travel are happy that a device plugged into the car handles most of the assembly of an IRS format mileage report so that they can receive their significant mileage deduction at income tax time

Mimicry

We are all being asked to innovate to insure the long term viability of our firms. Nature serves as a good model because evolution serves to highlight the best strategies. Modern behemoths like the 3500 Prince Die Casting machine at Cana-datum are a good example. Innovation, useful in the current marketplace, involves adding computer brain power to improve control and results. In the same fashion that the brontosaurus used multiple brains to achieve timely control, die casting machines work best when more than one computer is employed. In the same fashion that involuntary nerve reactions protect us from injury, some of the innovative new computer uses are simply mundane monitors. Higher level computer brain power can be dedicated to running the shot in much the same fashion as the brontosaurus had a whole brain dedicated to operating the rear legs. Computers embedded in devices like soft starter are particularly useful is reducing the peak electrical demand so that enough power is available to implement precision temperature control using hot oil systems without rewiring the plant.