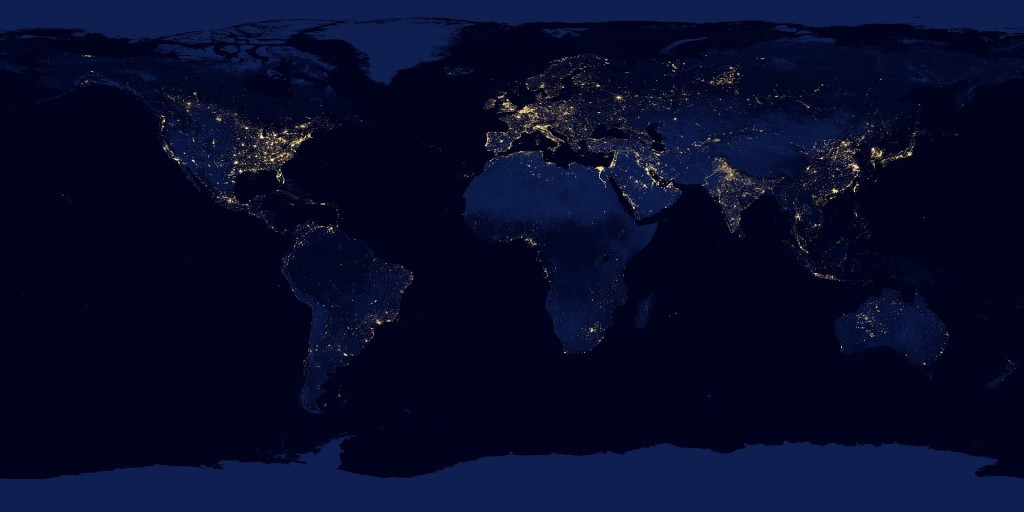

In the classic tale, 3 blind men encounter an elephant. Each of them gives a different report based on their encounter. A space traveler flying by earth would see a water world covered in oceans. While this is the most accurate approximation, it would totally miss the land masses that are home to the earth’s population. Just like the blind man in the tale, some people who live in the great deserts of the world lack the personal experience to confirm the wet nature of our world.

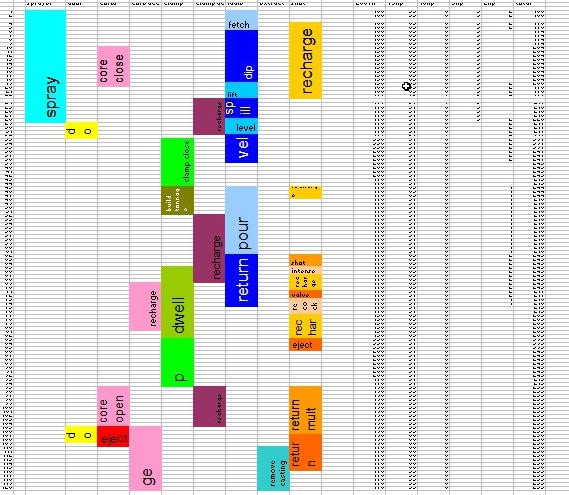

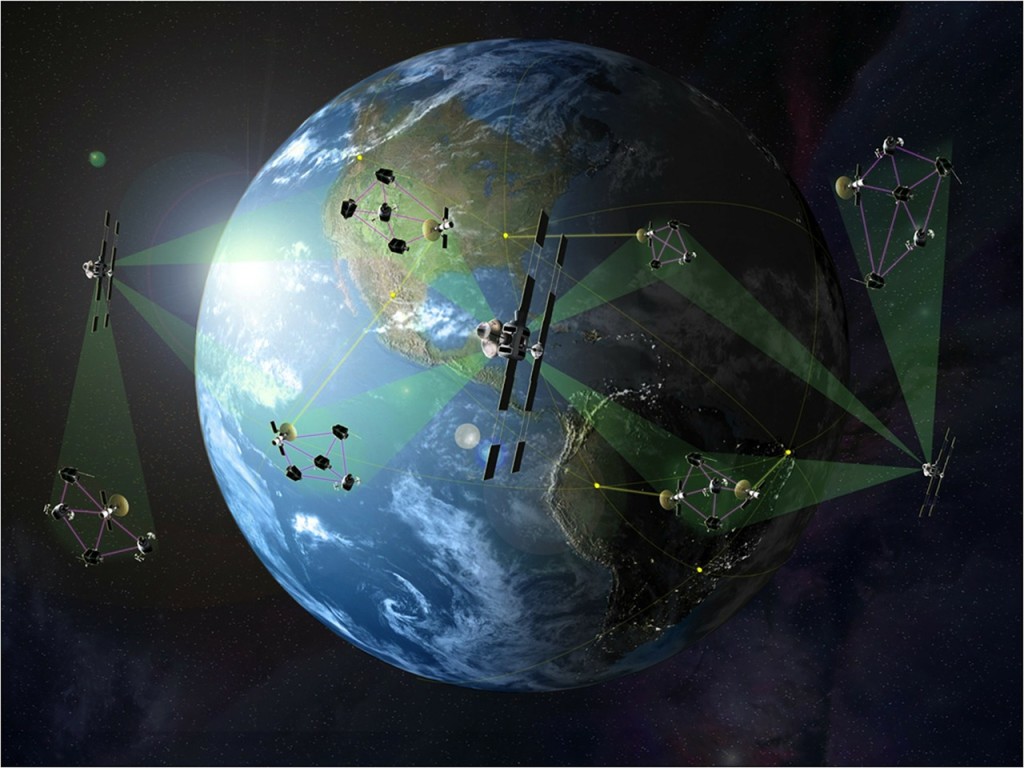

Quoting is an exercise that is based on approximations. Most customers are unwilling to wait for the time that it takes to assemble a fully detailed list of the costs required to supply a product or service. The pendulum would need to swing really far back for customers to pay for estimates. I have not seen engineers paid for creating cost estimates since my dad worked for an engineering consulting firm. Successful lean firms usually receive quote requests to supply most of the product sold in their industry. This is especially true if they have evolved to the point where they are normally one of the lowest cost bidders. Purchasing agents are evaluated based on their ability to secure the best price. One of their tools is removing suppliers who refuse to quote every job from their bid list. José Ignacio (“Inaki”) López de Arriortúa invented a cost cutting tactic which appeared to work, because if you ask enough suppliers to quote, someone would bid less that it costs. Disgrace finally caught up with him when he was forced to resign from VW. Volkswagen agreed to pay GM $100 million and to buy $1 billion dollars worth of parts from GM to settle Lopez’s misconduct. The poor Tier 1 estimators who were bombarded with an excessive Lopez-inspired barrage of quote requests, gained the ability to estimate quickly and triage. Spreadsheets with tuned approximations were invented. In triage fashion two-thirds of the quotes were returned with a quickly calculated price that was 35% over market. I can only imagine the effect of approximate high bid pricing on the cost planners at automotive headquarters. Usually you should make an assessment of the capability of the lowest bidders before you spend 2 billion dollars supplying them with custom tooling. The fact that this tooling never made a part for GM is also part of Lopez’s legacy. At this juncture the effect of this unnecessary cash flow on the GM bankruptcy is simply arm chair quarterbacking. I remember Neil Armstrong (a professor at the University of Cincinnati where I went to school) talking about the danger of space travel. “As an astronaut, you remember that the rocket is made by the lowest bidder.”

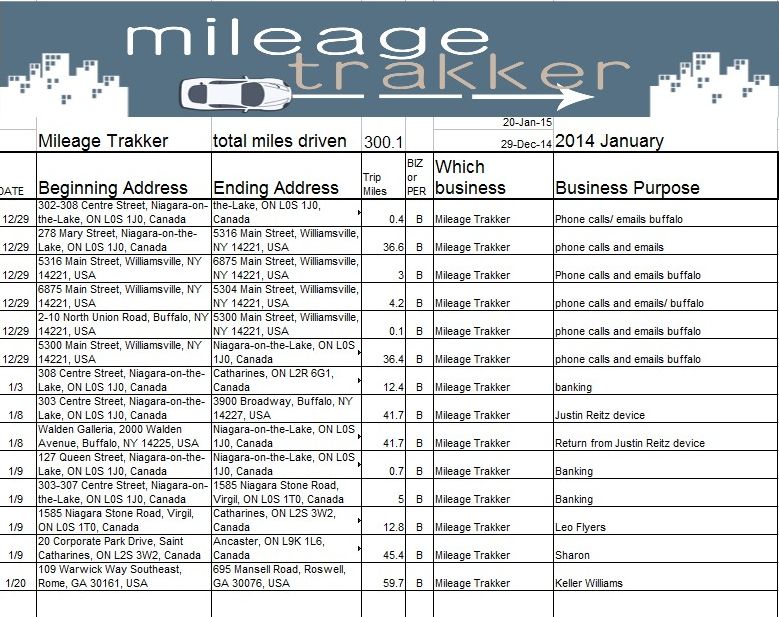

The IRS uses our tendency to save time by using approximations to their advantage. Yes, it is possible to compute your mileage deduction using the distances computed by MapQuest. I know this because I have spent many a Christmas holiday recreating the log of mileage needed to qualify for the deduction. Now that my http://mileagetrakker.com device generates an accurate log for me, I discovered that the approximate method left a bunch of money sitting on the table. Actual trips include gas stops, detours, errands, procurement stops, sales calls that usually get left off the recreated list. Having lived both methods, I understand how it happens. Most of my trips occur when my business is busy. It is unusual to have an extra second or two to record mileage when you are running behind.