It is easy to caught in the trap of hanging onto outdated beliefs. For this post I happen to choose bloodletting as the example because most people recognize that it has no or very little value. However it was the accepted good practice for over 2000 years. Adding a “lean” label to the practice of bloodletting does not change its usefulness. I also hope that the conspiracy theory people do not pick up on this post and attempt a revival of bloodletting.

Conspiracy theory proponents are not the only ones who can be confused by labels. The lean movement started as a strategy for adding more customers and sales volume in the most cost efficient manner. Within the original MVP (minimum viable product) concept is the word viable. To qualify as being lean, viability is required. Labeling other systems as lean that do not enforce viability can cause pitfalls. They fall into a few categories

a) Company liquidation systems (cost cutting)

b) Quality engineering abdication systems

c) Shortcut scientific method systems using only 4 of 6 steps

From Wikipedia

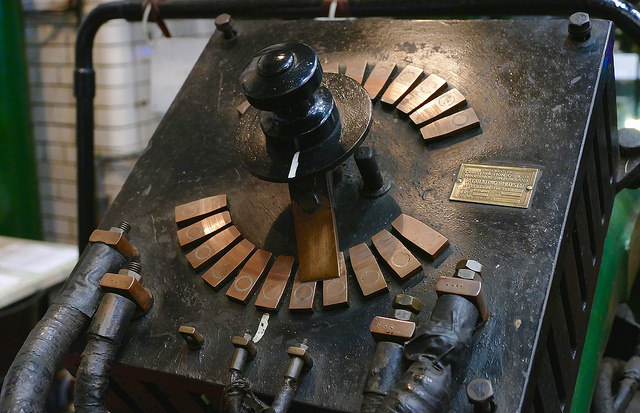

Bloodletting (or blood-letting) is the withdrawal of blood from a patient to prevent or cure illness and disease. Bloodletting, whether by a physician or by leeches, was based on an ancient system of medicine in which blood and other bodily fluids were regarded as “humours” that had to remain in proper balance to maintain health. It is claimed to have been the most common medical practice performed by surgeons from antiquity until the late 19th century, a span of over 2,000 years.[1] In Europe the practice continued to be relatively common until the end of the 18th century.[2] The practice has now been abandoned by modern-style medicine for all except a few very specific medical conditions.[3] It is conceivable that historically, in the absence of other treatments for hypertension, bloodletting sometimes had a beneficial effect in temporarily reducing blood pressure by reducing blood volume.[4] However, since hypertension is very often asymptomatic and thus not diagnosable without modern methods, this effect was unintentional. In the overwhelming majority of cases, the historical use of bloodletting was harmful to patients.[5]