There is a disconnect between the virtual and real world[/caption]

There is a disconnect between the virtual and real world[/caption]

As an technology leader I am attracted to the bright colors in the emerging virtual world. The hum drum real world seems so stodgy dull and grey. Especially in the winter. It is easy to get sucked into the easy to understand simplifications needed to make virtual reality possible. However bright and colorful the food looks in the virtual world it has no smell or taste and my stomach still growls with hunger pangs.

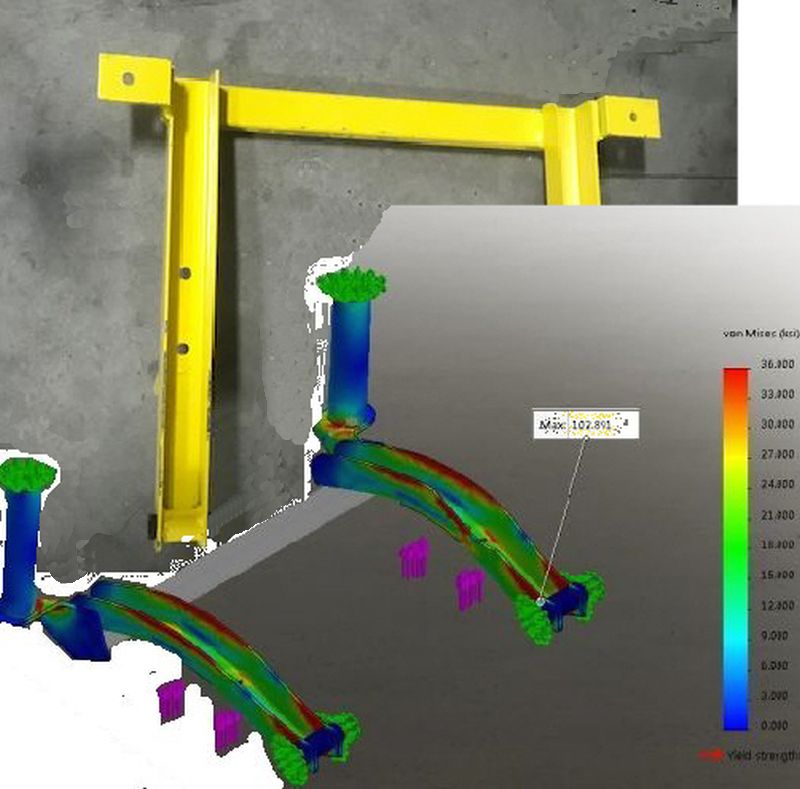

Computerized finite element stress analysis is a really powerful engineering tool. It is very helpful to know the effects of changes in part shape without going to the time and expense of building and testing actual components. In today’s rapid paced business environment the time saving that is possible is necessary to bring products to market before they are obsolete. I am currently using the technique to evolve a vehicle rear suspension into a version that will carry twice as much load

There is a difference between opinioneering and engineering. I think it is going to work is more risky than I performed a representative test and it passed. However much that I like virtual testing like finite element, the purchasers of my vehicles want them to work in more than the virtual world. Fortunately my latest test vehicle did not require the camouflage paint used for automotive test vehicles. In the automotive world, creative paint jobs hide the new model styling from the press. In most cases even a rigorous test program is not enough. I remember an automotive rear suspension frame like I am currently designing that did not show its weakness until some actual vehicles were out on the road. A panic stop while traveling in reverse buckled the rear axle under the vehicle. Not funny when this occurs after the frame was production tooled.

In most cases even a rigorous test program is not enough. I remember an automotive rear suspension frame like I am currently designing that did not show its weakness until some actual vehicles were out on the road. A panic stop while traveling in reverse buckled the rear axle under the vehicle. Not funny when this occurs after the frame was production tooled.

Agile product development addresses some of this issue. In agile fashion, we accelerated placing our new generation of rear suspension arm in actual customer use much earlier in the launch process. This adds a reality check to the computer assisted design and testing.

Disconnect

Reply