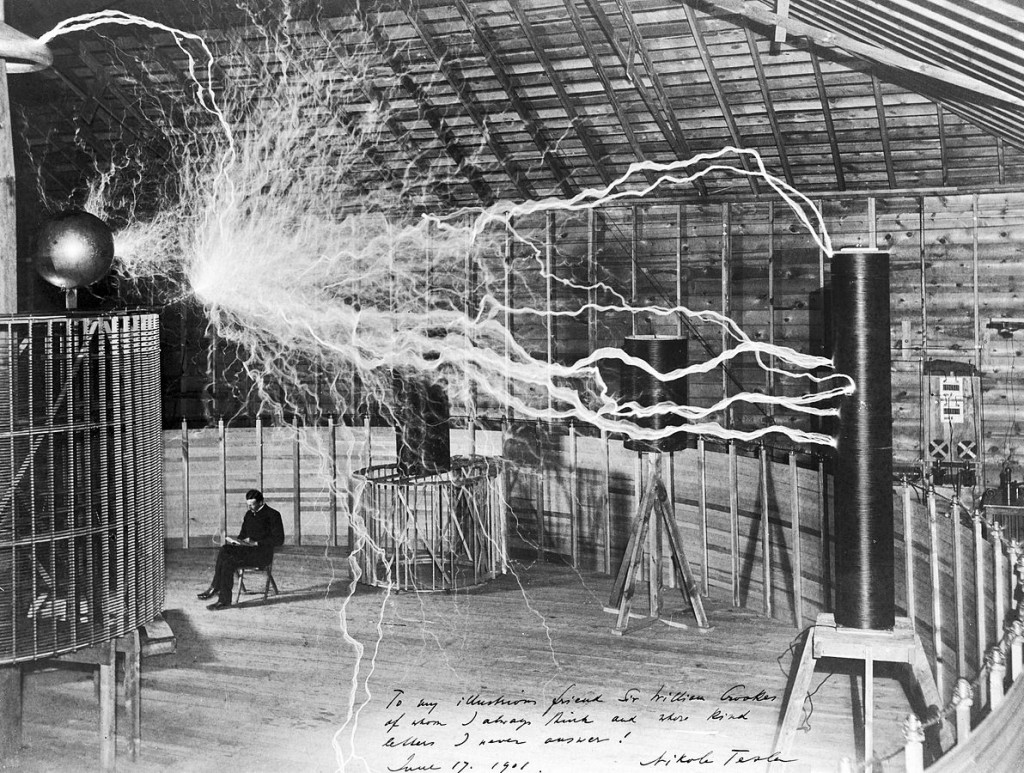

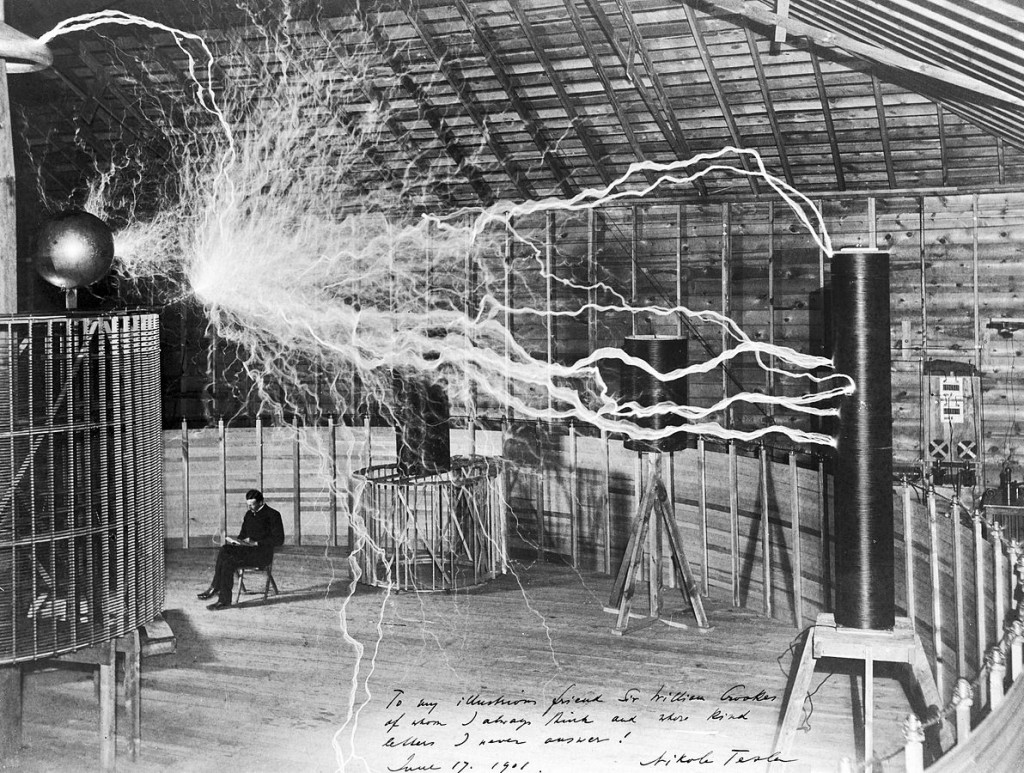

A multiple exposure picture (one of 68 Colorado Springs images created by Century Magazine photographer Dickenson Alley) of Tesla

au courant

Per Merriam Webster

adjective au cou·rant \ˌō-ku̇-ˈräⁿ\

Simple Definition of au courant

Popularity: Bottom 50% of words

: knowing about the newest information, trends, etc.

: stylish or current.

The 19th century started with the battle of the currents. Thomas Edison battled with George Westinghouse and Nikola Tesla. The DC current generating system invented by Edison was less suitable for transmitting current over large distances. Westinghouse put in place a 3 phase AC system invented by Tesla at a generating plant beneath Niagara Falls to supply power to the businesses of Buffalo. The big advantage of AC was the ability to use a simple transformer to change the voltage. High voltage transmission lines make long distance transport of electric power affordable. The original 25 cycle AC morphed into the 60 cycle AC power grid that spans the country. DC power faded into battery powered applications like car starter motors and flashlights.

Even though the transistor was invented in 1947, it remained a low power DC device into the 80’s. Chrysler invented an electronic spark advance and introduced it in 1978. It was taken out of service in 1980 because the ballast resistor needed to protect the power transistor proved to have a poor service life.

Balast resistors protected the power transistor running the spark coil until 1982 picture by Mr Choppers

Finally in 1982 we had a transistor that could successfully process a higher amperage 12V DC application. We no longer think about changing points and plugs. This used to be a biannual ritual.

Even for the engineers leading the charge into the bright new future, technology advances catch us by surprise. Moores law on the ever increasing number of transistors on a chip is well known. Other related advances in silicon power transistors seem to happen invisibly. We all got used to 12 volt DC vehicle power systems. Now with have hybrids and electric vehicles with DC voltages north of 800 volts. Driving this charge is the serious drop in the price of power transistors. I was reading about a tiny DC to DC voltage converter that can squeeze a whole bunch of extra life out of a simple dry cell battery.

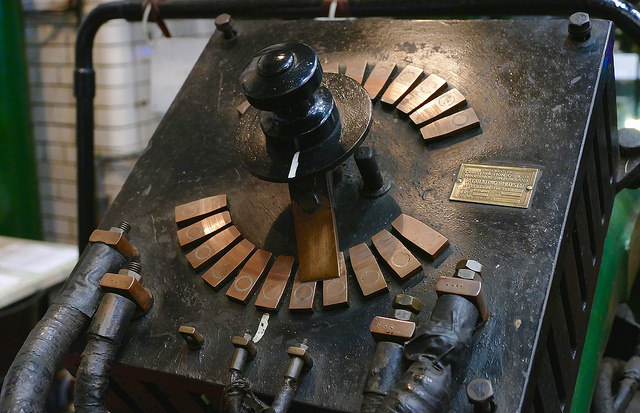

DC to Dc voltage converters have dramatically dropped in price

The harder part is switching gears myself and utilizing inexpensive 48 volt DC to 24 volt DC converters when designing my current new electric vehicle offering. They are a surprisingly good match to low current LED lighting.

DC current will splash back onto the public stage. We are seeing it already in very long distance transmission lines, electric vehicles, superconductive materials. The development effort needed to bring this to pass has been going on for a while. To the observing public the change will appear to happen overnight.